Rotating Machinery Condition Monitoring System

Using Acoustic Wave (Acoustic Emission)

- System

- V & AE

- Data Analysis

- Case Study

Condition monitoring usually refers to obtaining, tracking, and alerting the health status of the device by reading and analyzing sensor data installed on the device.

Vibration testing has been widely used in rotating equipment condition monitoring currently. However acoustic emission (AE) technology can detect earlier stage of damages or failures than using vibration.

The condition monitoring system is suitable for bearing condition monitoring and lubrication condition monitoring of various machinery including but not limited to:

- Gear box

- Centrifugal fan/pump

- Steam/gas turbine

- Centrifugal separator

- Generator

- Motor

- Centrifugal compressor

- Hydraulic turbine

- Aircraft engine

- Grinder

Products for Condition Monitoring

RAEM1

RAEM1 is the IoT-AE wireless single channel monitoring system.

- Wireless communication wired power supply

- Signal triggering and 24/7 working

- Remote control and configuration

- Suitable for the transient signals such as cracking

RAEM2

RAEM2 is the IoT-AE wireless all-in-one monitoring system.

- Sensor, processor, communication and battery built-in

- Time triggering and power saving for long term monitoring

- Low cost wireless remote automatic operations

- Suitable for unattended leak, wear, lubrication monitoring

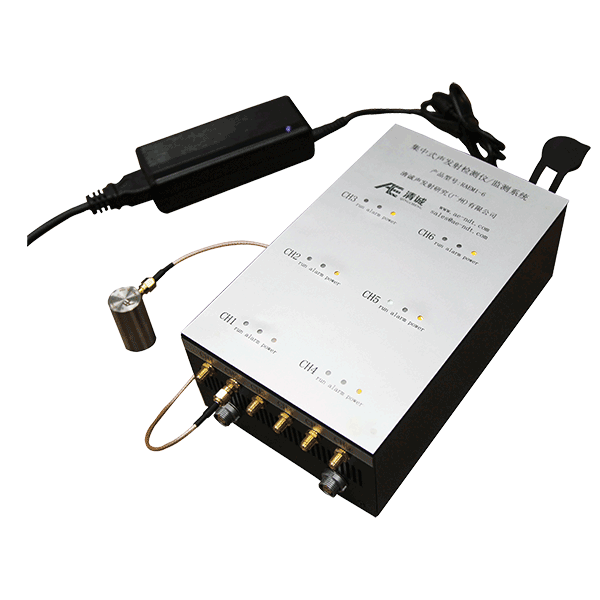

RAEM1-6

Multi-channel testing or monitoring system

- Multiple sensors networking to locate the accurate defect locations for large machines

- Suitable for precise crack location for condition monitoring

Installation:

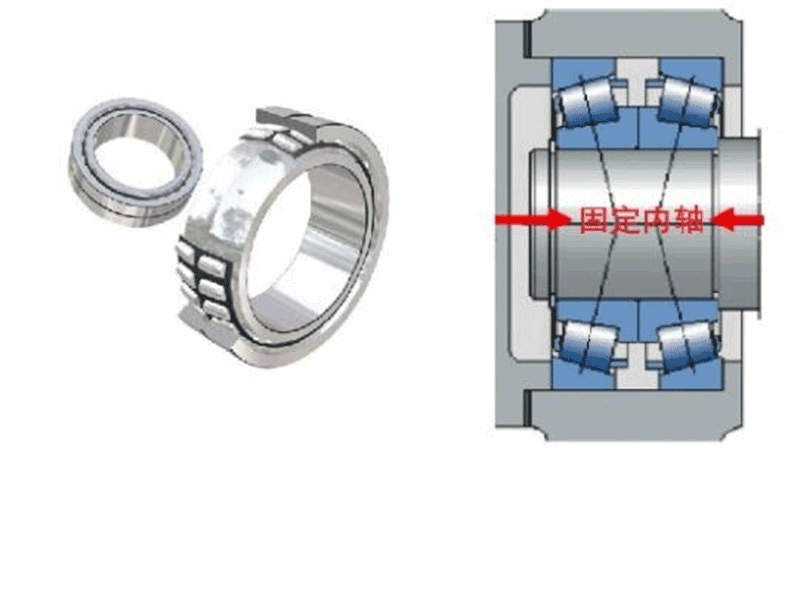

The sensing parts are coupled on the fixed part of a rotating device. Multiple monitors can form a multi-channel monitoring system for real-time monitoring of large equipment.

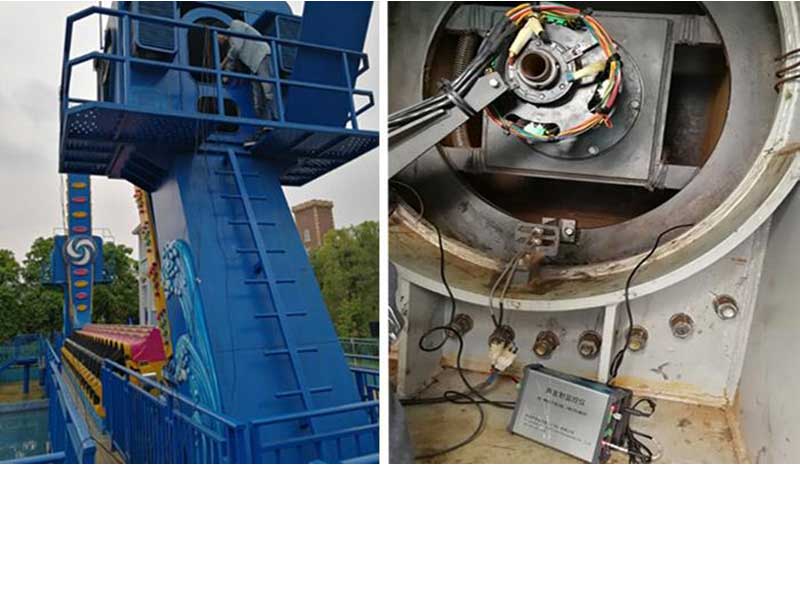

For example, when monitoring the rotating components such as amusement facilities, the monitor should be far away from the position of bolt connection and support as far as possible; In local monitoring, the measured part should be located in the middle of the monitor array.

Procedure

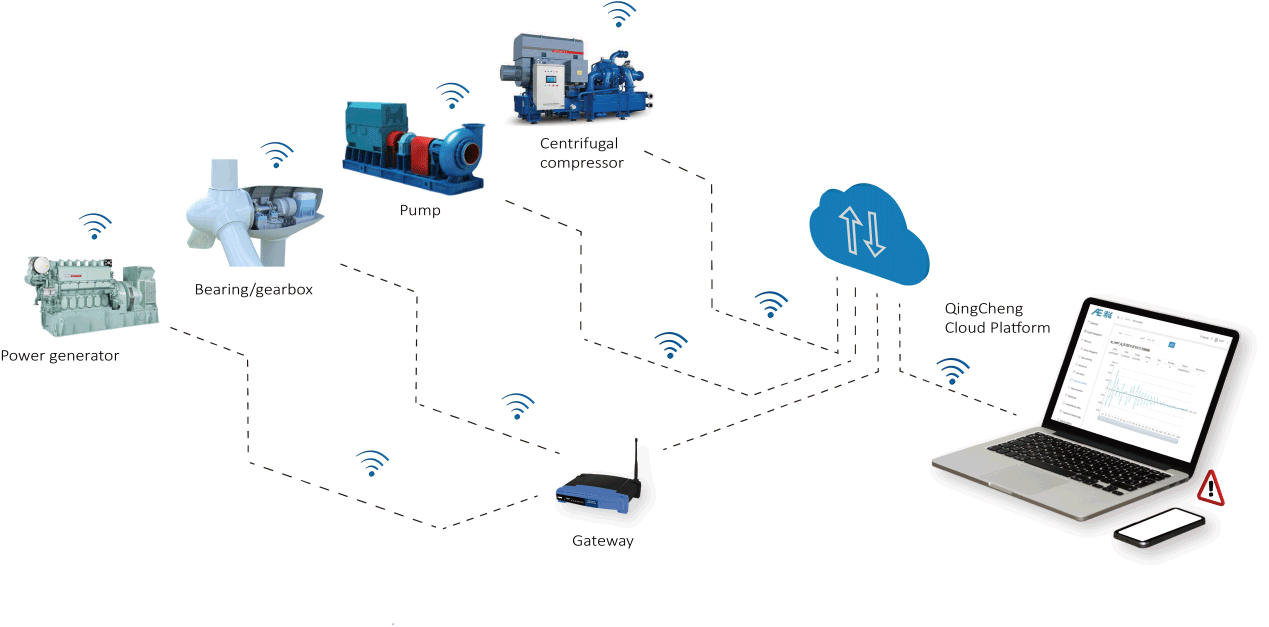

- Rotating equipment (bearing, gear box, etc.) needs 1-8 devices.

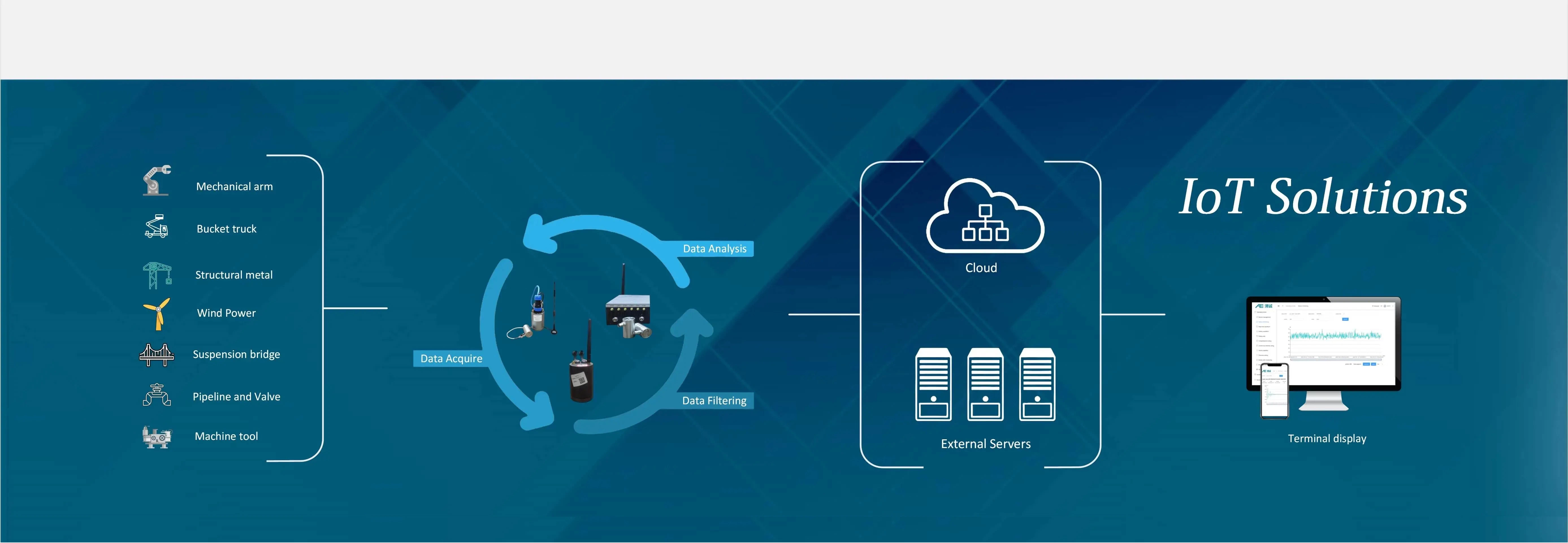

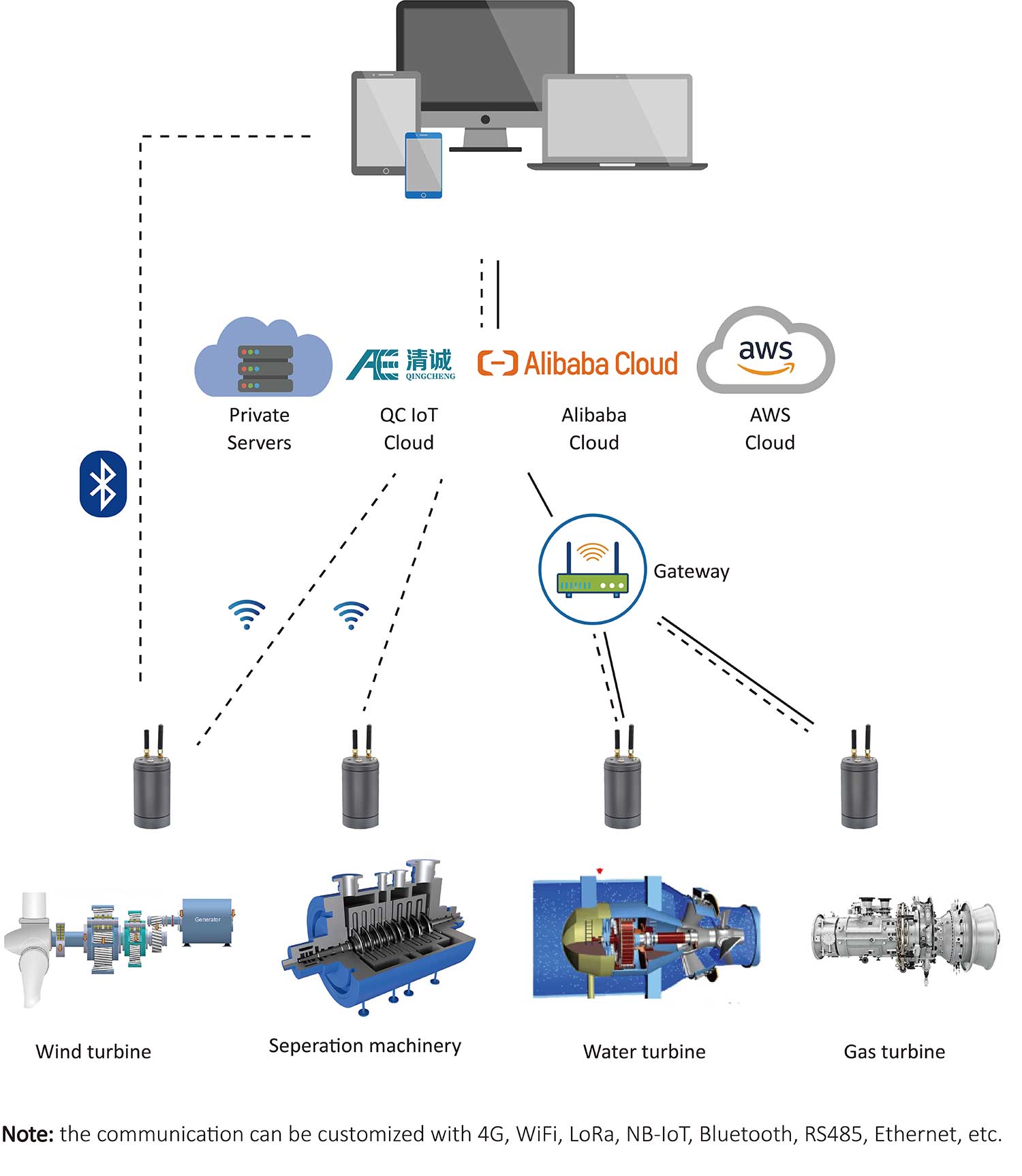

- The RAEM communicates with central control server, monitoring screen or IoT platform though Wi-Fi or gateway or 4G.

- Timing start and sleep system, timing data acquisition.

- Obtain criteria standard from data analysis and processing.

- Alarm information based on the criteria.

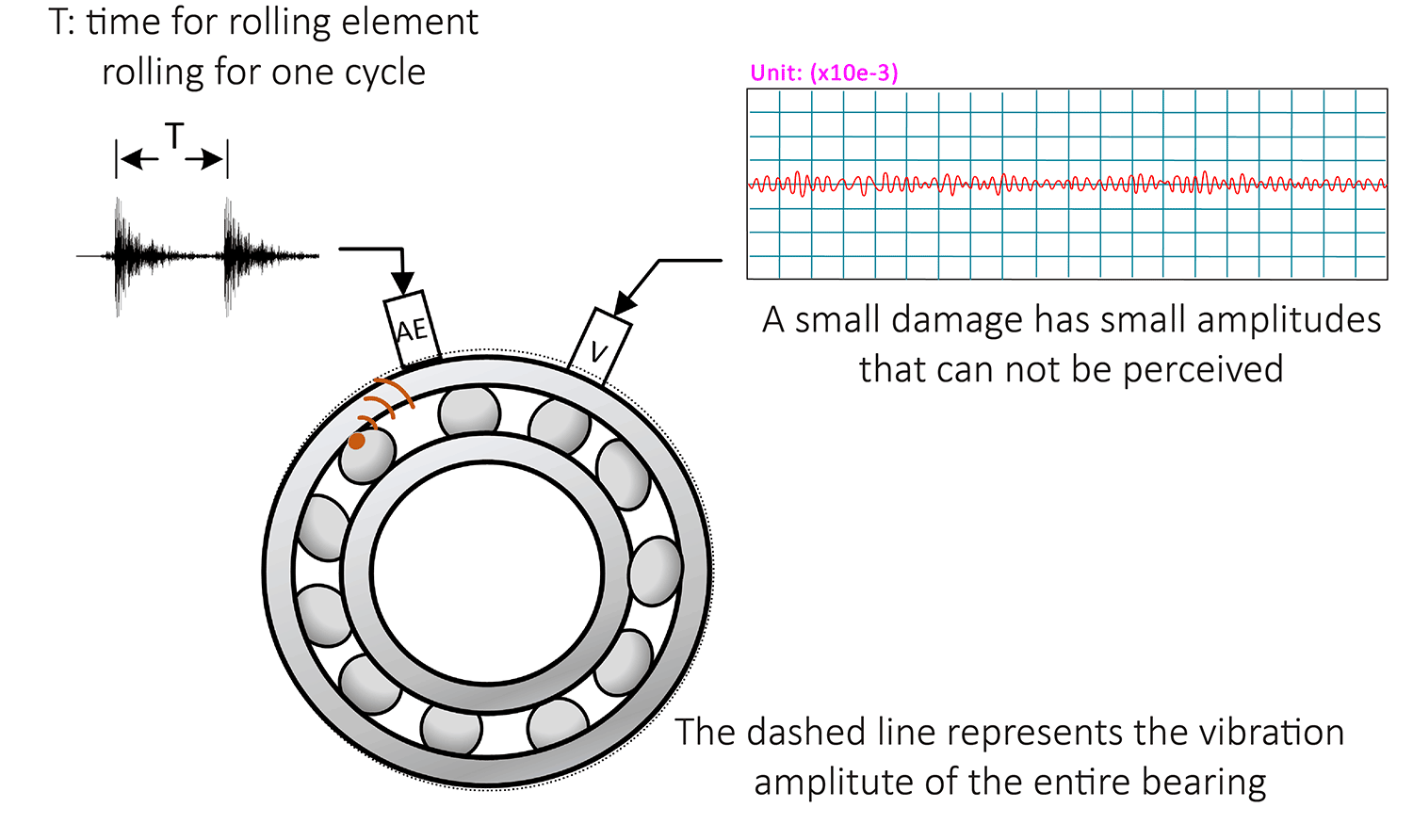

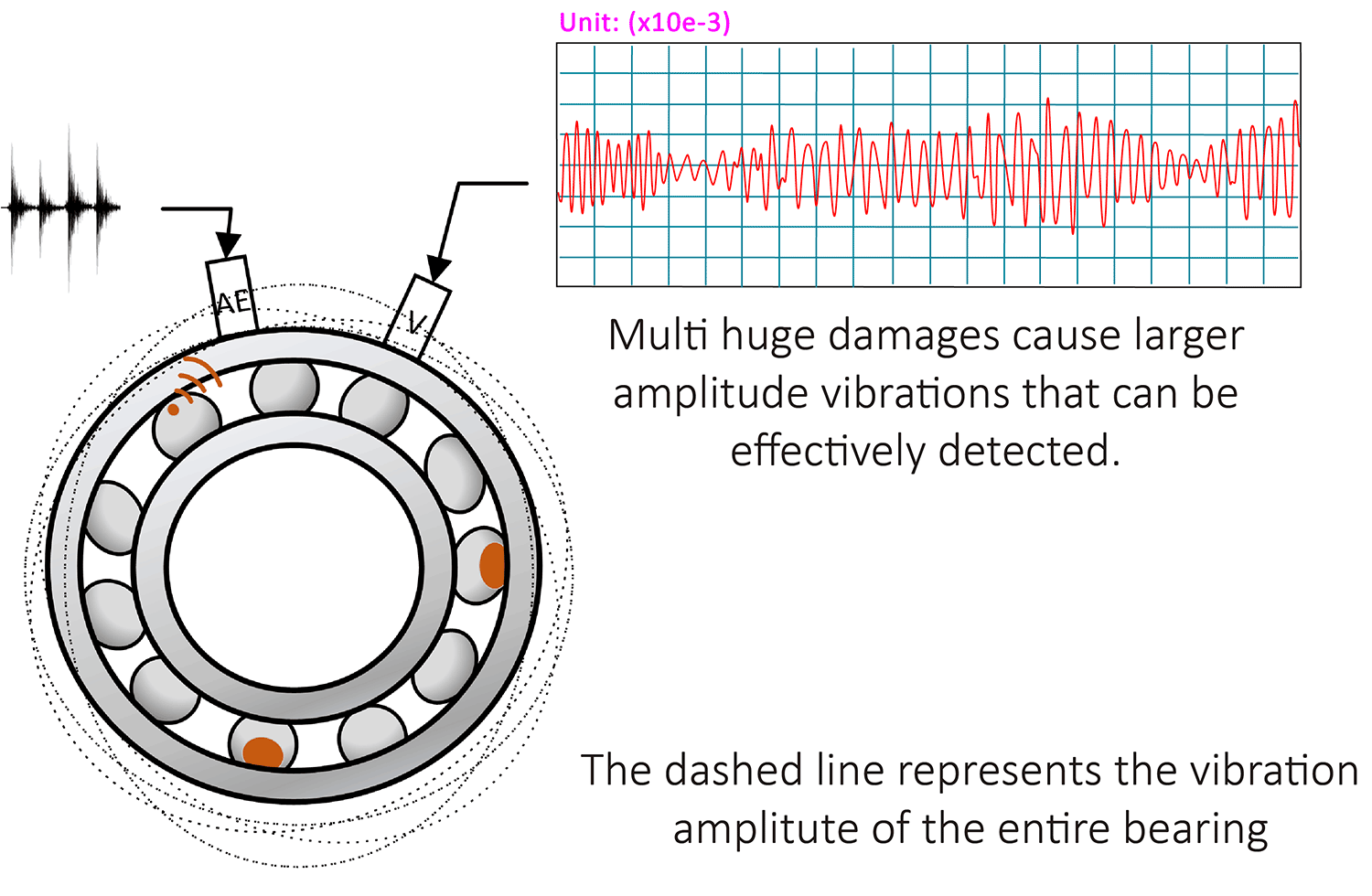

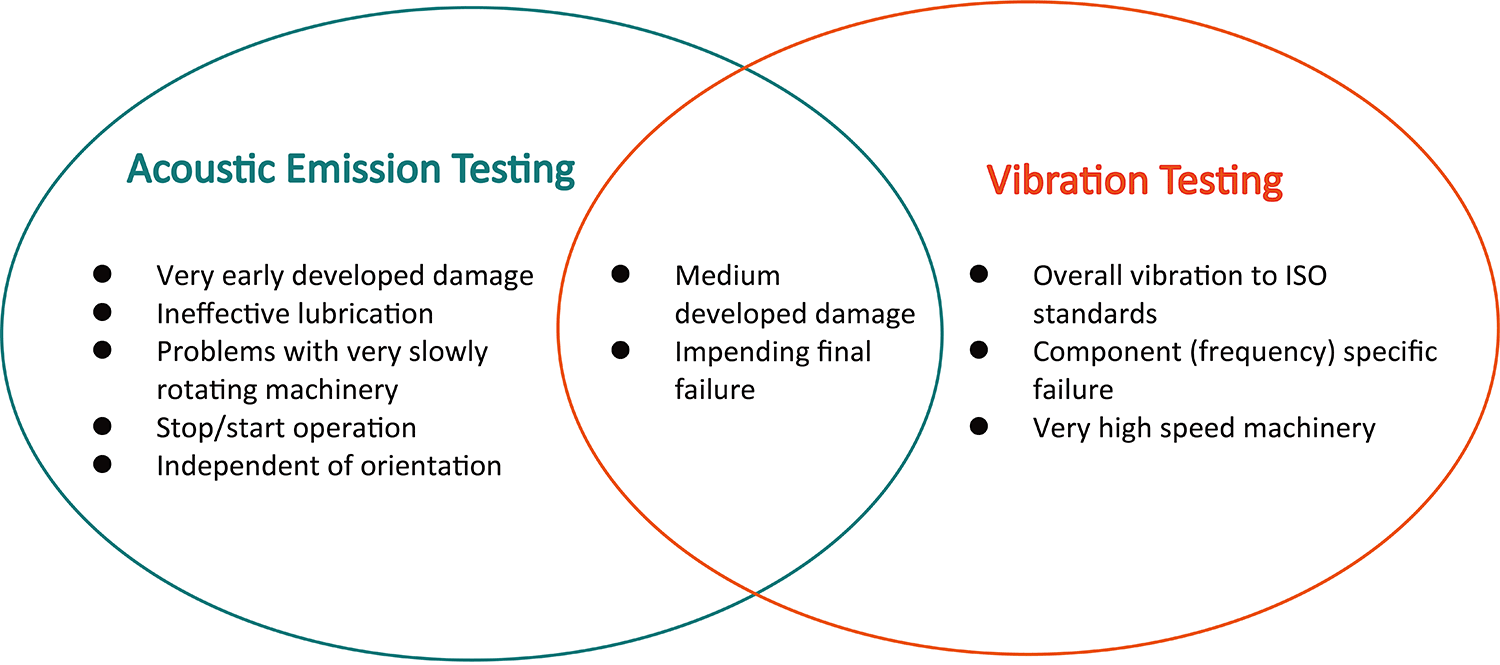

Vibration vs. Acoustic Emission

Vibration testing has been widely used in rotating machinery condition monitoring currently. But acoustic emission technology can be also used in condition monitoring in rotating machinery plus more advantages.

Acoustic waves are generated when rotating equipment is operating, including those audible to human ears and those outside the audio range that cannot be heard by human ears. The acoustic wave should have a different spectrum for different states (normal operation,wear, lubricant contamination and deterioration, etc.). The acoustic wave is received and analyzed by our RAEM system. The corresponding state is obtained through qualitative and quantitative analysis and uploaded and alarmed by the cloud platform of the Internet of Things.

Acoustic Emission Testing

- Detect the acoustic waves from the local sound source.

- For both transient and stead-state signals, such as cracking or wear.

- Detect low & high frequency signals.

- The sensor must be installed on the surface of the detection object.

- High sensitive to local states and intial damages.

Vibration Testing

- Detect the overall vibration of the whole structure.

- Just for steady-state signals, such as wear or corrosion.

- Detect low-frequency signals.

- Sensor is unnecessary to install on the surface of the detection object.

- Low sensitive to the local states and initial faults.

Display & Analysis

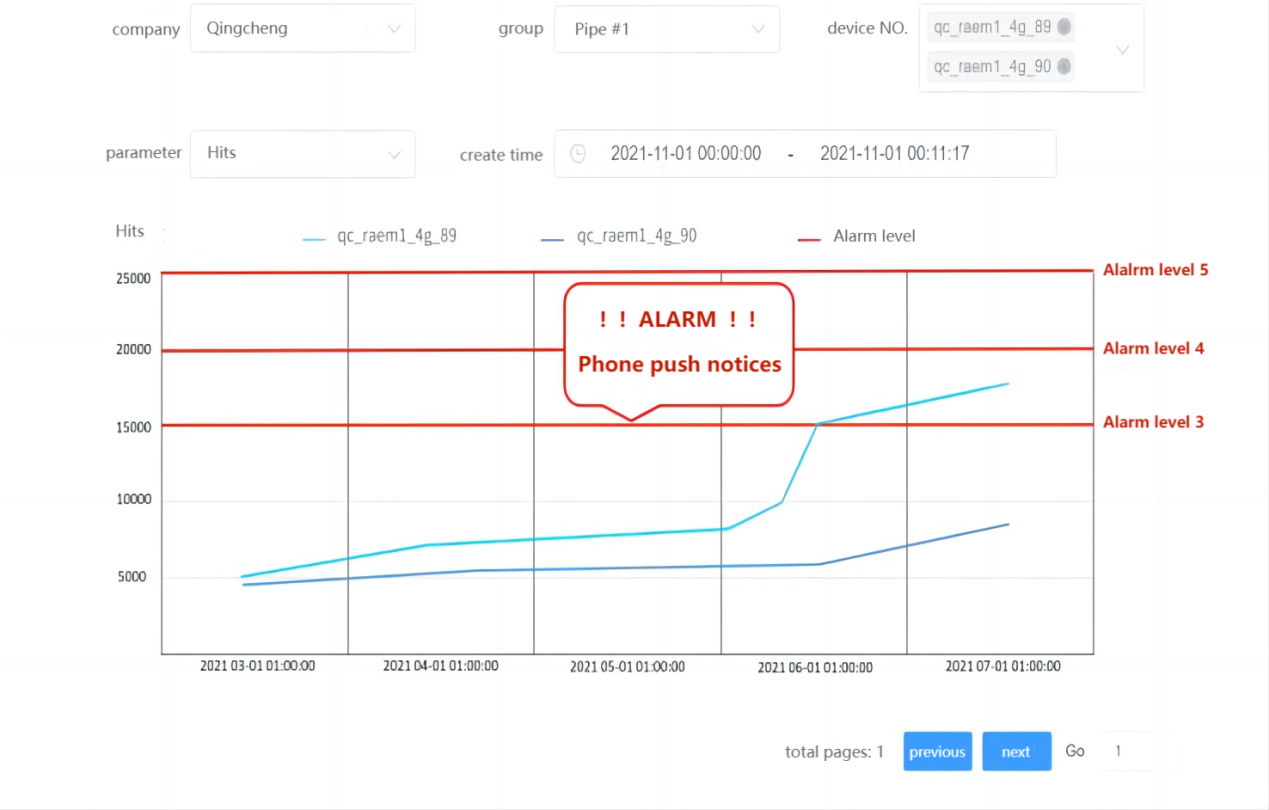

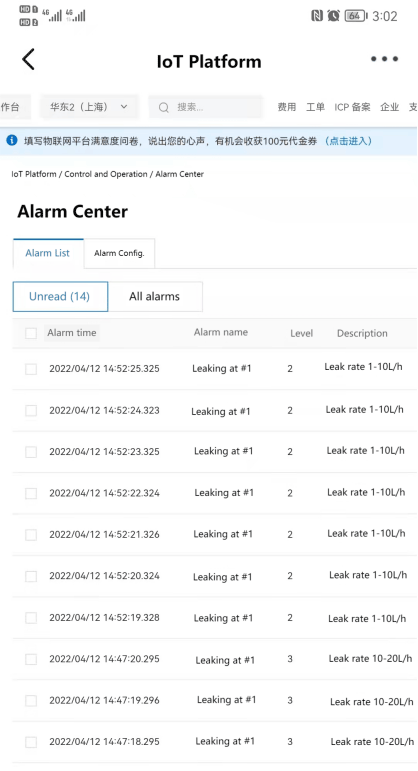

Qingcheng IOT Cloud Platform, Alibaba Cloud, AWS and more platforms are available to use as the data terminal for display, storage and analysis. Below lists the QingCheng IoT Cloud Platform features as examples:

- Real-time AE parameters and waveform displays

- Remote control and configure the devices

- Historical data storage and downloads

- Remote system firmware upgrade

- Parameter values rating to trigger alarm notifications for abnormal activities

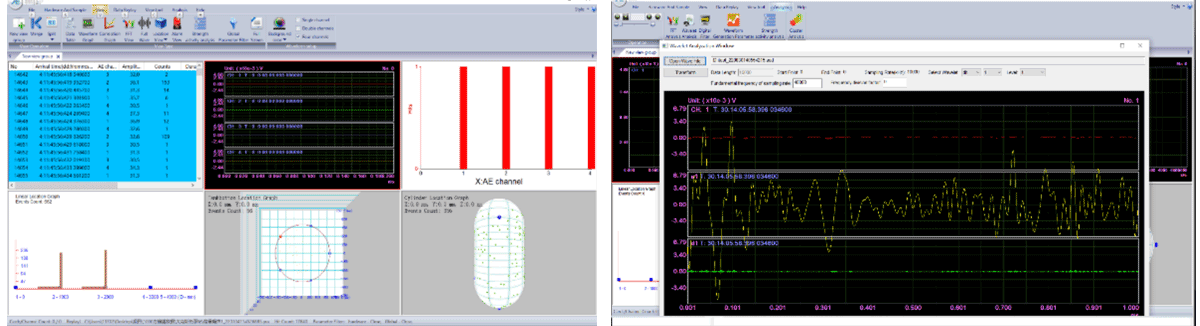

2) SWAE software for SAEU3H/RAEM1-6

The SAEU3H or RAEM1-6 system can use the SWAE analysis software to analyze the real-time data and also for post data analysis.

- Various views and analytical functions, location analysis, correlation graph analysis, waveform analysis, Fast Fourier Transform, wavelet transform and more;

- Data storage and exportable to other formats for third party analysis.

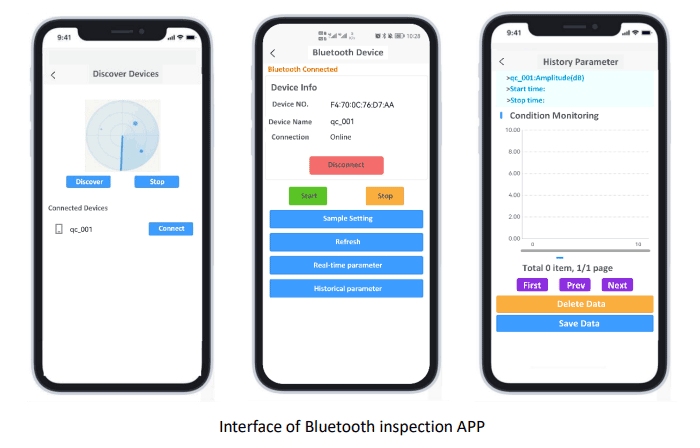

3) Smartphone App using Bluetooth for RAEM2

- Real-time parameters and waveform display

- Historical waveform and parameter query (parameters are amplitude, average signal level (ASL), energy, RMS; the display time accuracy is in minutes)

- Device control and configurations

Contact Form

Please complete the form below to request your quote. We will be in contact as soon as possible.