Pressure Vessels/ Tanks: Testing and Monitoring System

Using Acoustic Wave (Acoustic Emission)

Storage tanks, pressure vessels and boilers are required to take regular inspections and testing to ensure the safety of continuous operations and the integrity of the vessels in case of corrosion, cracks and leaks.

The national and industrial standards of the pressure vessels inspection include some non-destructive testing methods, for example, radiographic testing, ultrasonic testing, eddy current testing and magnetic particle testing. However, another NDT technology, acoustic emission testing (AET) has unique advantages of non-stop operations or no need to drain or open the vessels, which makes the AET a faster and cost-effective technology for:

- Tank inspection

- Storage tank monitoring

- Pressure vessel detection and monitoring

Principle

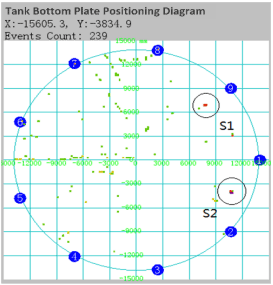

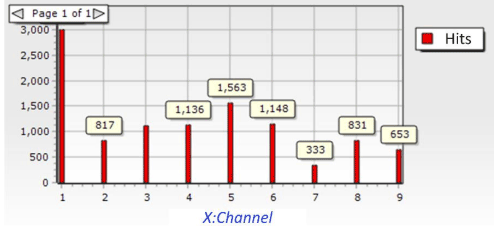

When there are the cracks, corrosion or leak, the storage tanks or pressure vessels generates acoustic elastic waves that can be captured by the acoustic emission sensors following by processing and analysis to locate the sources.

Video

Video

Products

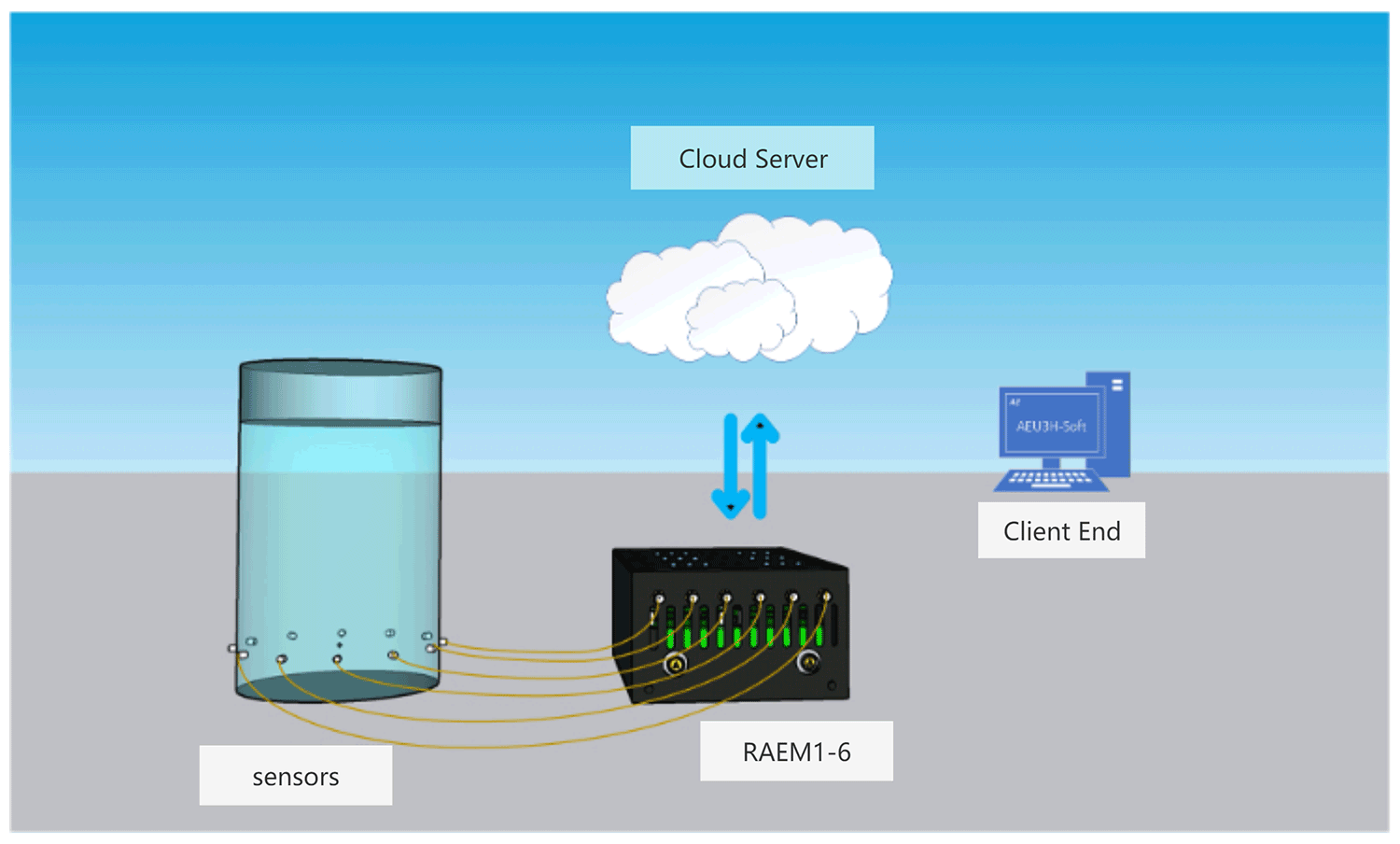

According to the customers requirements, we provide two kinds of AET systems to meet periodical detection requirements and long-term monitoring needs.

| Periodical Detection | Long-term Monitoring | |

|---|---|---|

| Photo |

|

|

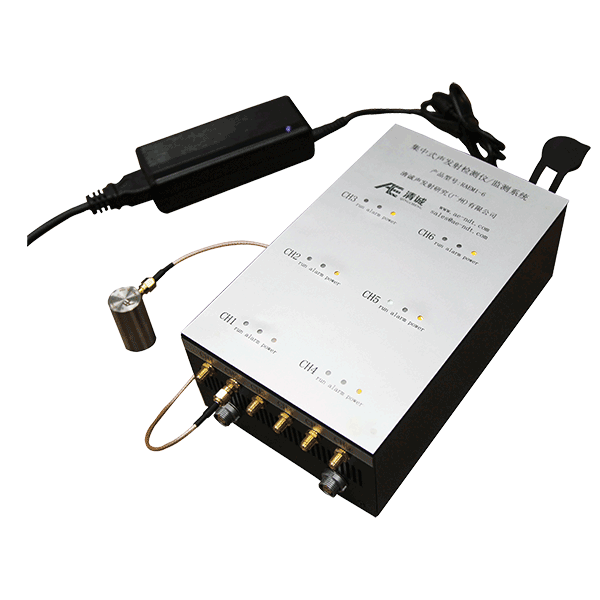

| Detection system | SAEU3H acoustic emission detection system | RAEM1-6 acoustic emission monitoring system |

| Operation system | Windows | Linux |

| Channels | Multi-channel, cascadable to 100+ channels | From 6 channels, cascadable to 100+ channels |

| Acoustic emission sensors |

GI40/G40 for tank bottom corrosion; GI150 for tank body cracks |

GI40/G40 for tank bottom corrosion; GI150 for tank/vessel body cracks |

| Sampling rate | 10M/s, 16-bit | 2M/s, 16-bit |

| Waveform collection | Support | Support |

| Analog filters |

High-pass filters: 20kHz, 100kHz, 400kHz Low-pass filters: 100kHz, 400kHz, 1200kHz |

High-pass filters: 30KHz, 125KHz Low-pass filters: 80KHz, 175KHz |

| Digital filters | 1KHz-2.5MHz | 1KHz~1.0MHz |

| Advantages | USB3.0 high-speed data transmission, good expansion ability, stable performance, accurate defect location function. Suitable for regular detection. | Based on Linux operating system, stable performance, wireless communication capability, suitable for long-term remote unattended monitoring. |

User Cases

Further Information

Contact Form

Please complete the form below to request your quote. We will be in contact as soon as possible.