Acoustic Emission Testing of Storage Tank Floor in Cuban National Oil Company (CUPET)

Brief:The test was carried out in accordance with the Chinese machinery industry standard JB/T 10764-2007 “Atmospheric Pressure Metal Storage Tank Acoustic Emission Detection and Evaluation Method”

Fig. 1 Field storage tank picture

Tank serial number: TK-56, put into service in 2012

A516-Gr70 Diameter: 74 meters, design liquid level 10.8 meters, material A516-Gr70.

The loading history of nearly a month showed that the highest liquid level had reached 10.6 meters, and the liquid level was planned to rise to 10.8 meters in this test.

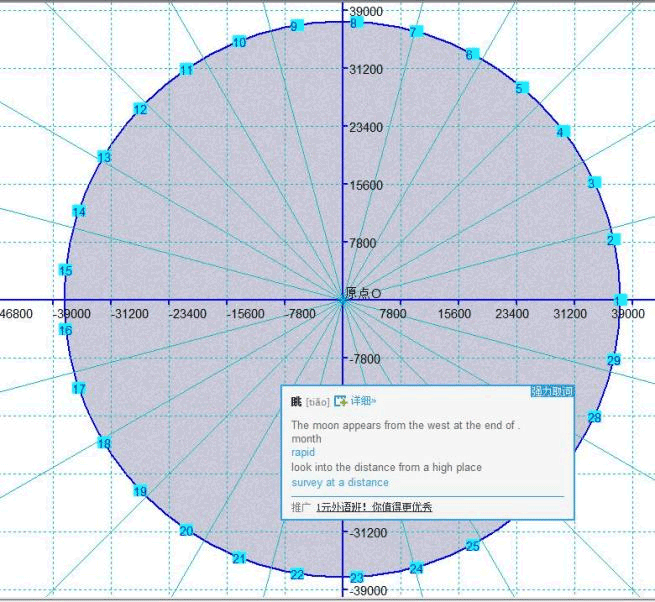

Decide the sensor installing positions according to the circumference of tank, the actual number of channels used: 29 channels

Sensor spacing: about 8 meters

Fig. 2 Diagram of AE source location of tank floor corrosion

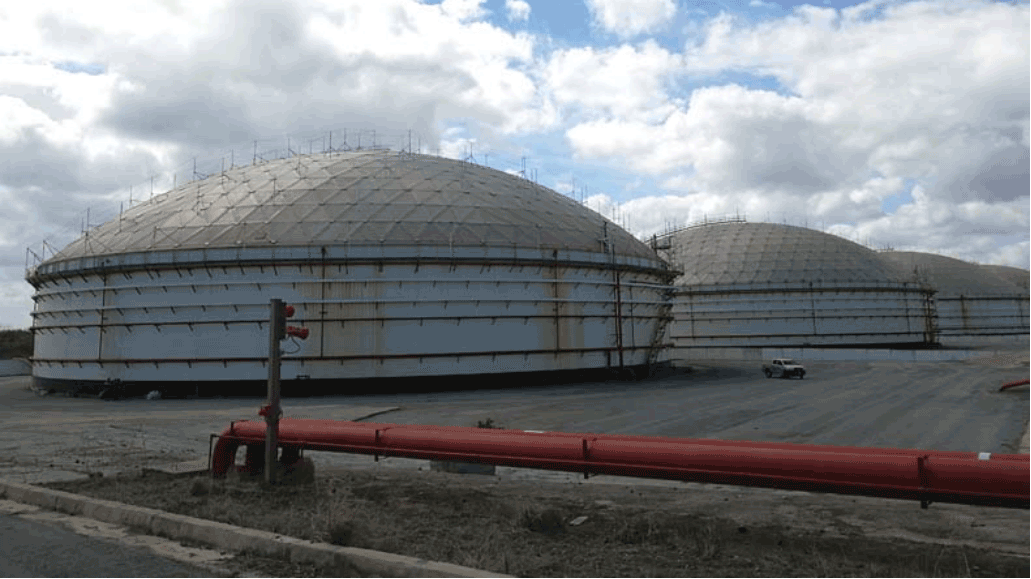

Fig. 3 Field inspection picture

Instrument used: Qingcheng’s (prev. Beijing Soundwel) SAEU2S-32, which consisted of two 16-channel hosts cascaded into 32 channels. Sensors used were SRI40 with built-in preamplifier.

Fig. 4 Field inspection picture

Since there was no power supply on site, the instrument was powered by gasoline generator +UPS power supply.

The test was carried out in accordance with the Chinese machinery industry standard JB/T 10764-2007 “Atmospheric Pressure Metal Storage Tank Acoustic Emission Detection and Evaluation Method”

Finally, a comprehensive inspection was conducted on the storage tank group of the Cuban National Oil Company, and based on the distribution of impact numbers, a specific implementation plan for tank opening and retesting was determined. And based on the opening results, they established the qualification standards for subsequent annual inspections.