Structural Integrity Monitoring System

Using Acoustic Wave (Acoustic Emission)

1 Introduction

1.1 Application Scenes

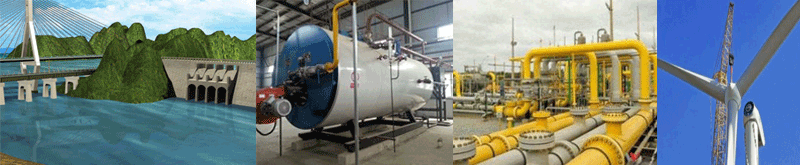

Structural health monitoring (SHM) means by monitoring some essential parameter values to evaluate the structural integrity and health conditions and plan predictive maintenance to reduce downtime and maintenance costs. SHM can be applied on various structures, materials and equipment, such as bridges, wind turbines, tanks, pressure vessels, aerial work platforms, or any structural or material components. For example, cracks in metal and non-metallic structures such as bridges and dams, petrochemical tanks or pressure vessels, valves and pipelines, etc.

Acoustic wave (acoustic emission) technology has advantages of detecting the initial cracking and monitoring the crack growing dynamically without stopping operations and shutdowns. Therefore, compared to other NDT technologies, acoustic emission technology is one of the time and cost effective methods for structural health and integrity monitoring.

1.2 Technical Principles

The damage processes such as cracks, deformation and delamination in structural materials are often accompanied by sound waves (acoustic emission). The sound wave is acquired and analyzed, and the type, degree and location of damage can be determined by the acoustic wave (acoustic emission) system, and a health assessment can be made on the integrity of structural components.

2 Solution - RAEM1 remote Acoustic Wave (Acoustic Emission) monitoring system

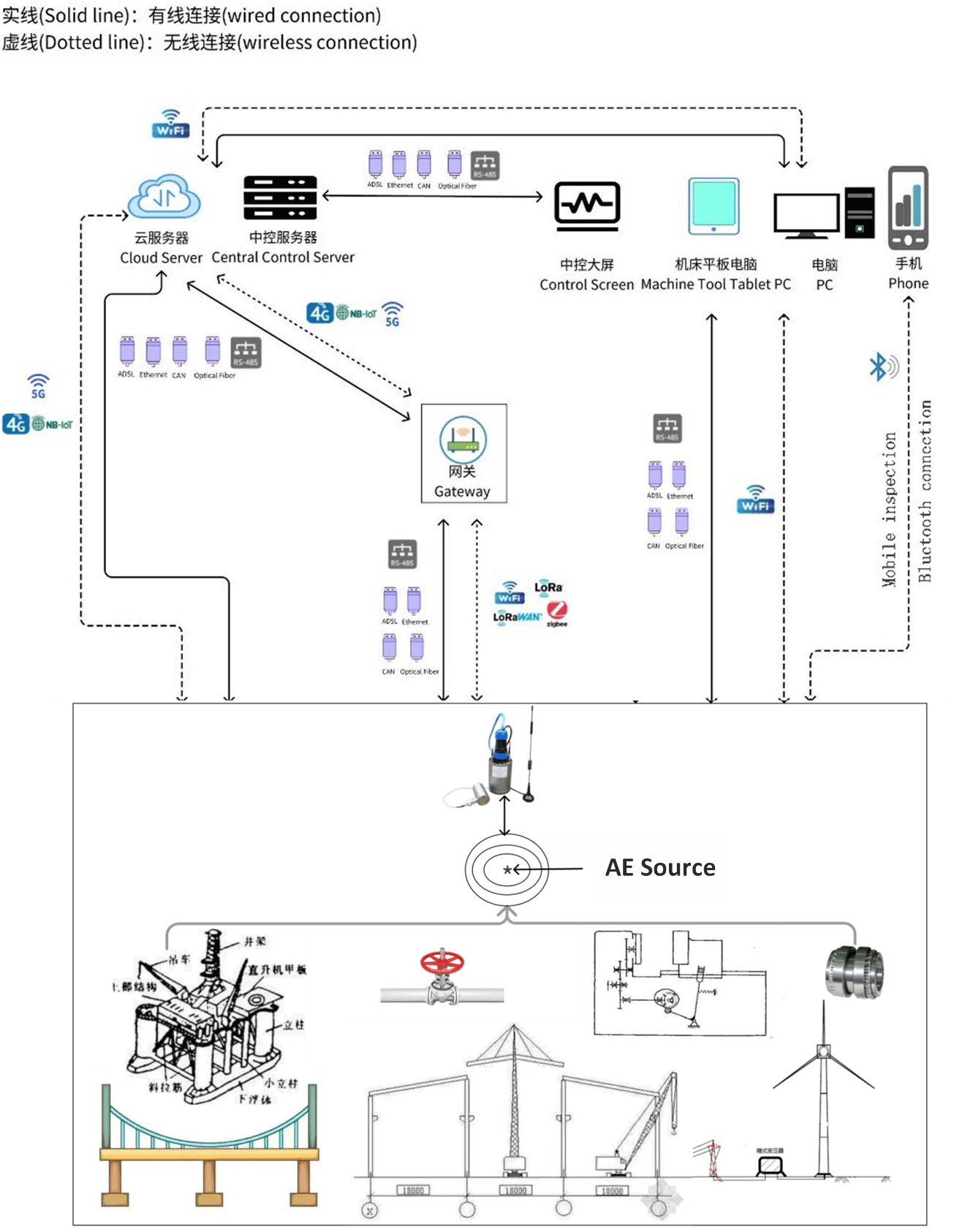

System diagram

A variety of data output communication modes (Wi-Fi, 4G, Ethernet, RS485, etc.) can be configured according to user requirements to achieve regular scheduled detection, local long-term monitoring, and remote long-term monitoring and other application modes.

Note: The above systems have the functions in mobile app with Bluetooth communication for inspections and on-site debugging settings.

2.1 Features

- All year round online monitoring

- Automatically acquire and process AE data and provide evaluation results

- IoT remote connection and transmission

- Real-time and historical data display and analysis online or in local software

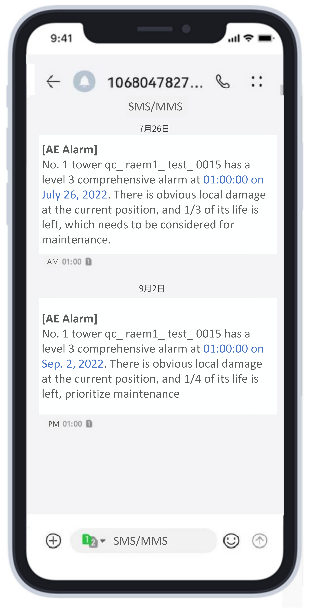

- Real-time alarm notifications via SMS or emails

The online Cloud platform automatically displays the results

Automatically alarm information

3 Main Hardware and Software Introduction

RAEM1 remote Acoustic Wave (Acoustic Emission) monitoring system consists of:

| RAEM1 | Sensor |

| Acquisition & Processing Circuit | |

| Communication modules | |

| Platform | Cloud / software / APPs |

| Client Terminals | Smartphones / PC / Servers |

Multiple RAEM1 can be composed of a multi-channel real-time monitoring system for a large structure.

3.1 Detailed System Options for SHM Applications

RAEM1 |

Sensor (with built-in preamplifier) | GI40 for non-metallic object surfaces | |

| GI150 for metal object surfaces | |||

| Acquisition & Processor | Analog filters, digital filter, ADC etc. | ||

| Communication module | Wired | RS-485 | |

| CAN | |||

| LAN | |||

| Wireless | 4G | ||

| WIFI | |||

| Bluetooth (Mobile phone APP) | |||

| LORA (Networking) | |||

| Terminals | Phone | APP | |

| Mini program | |||

| SMS | |||

| Cloud platform | Qingcheng IoT cloud platform | ||

| Alibaba Cloud | |||

| AWS (Amazon Web Services) | |||

| Software | SWAE analysis Software | ||

| RAEM Configuration Software | |||

| Data Format | AE Parameters | Arrival time, amplitude, counts, energy (power), rise time, rise counts, duration, RMS, ASL, peak frequency, centroid frequency, 5 partial power spectra segments | |

| Waveform | Sensor output waveform in time domain | ||

| Ratings | Evaluations of the results to trigger different alarm levels | ||

3.2 Software and Platform Data Display Examples

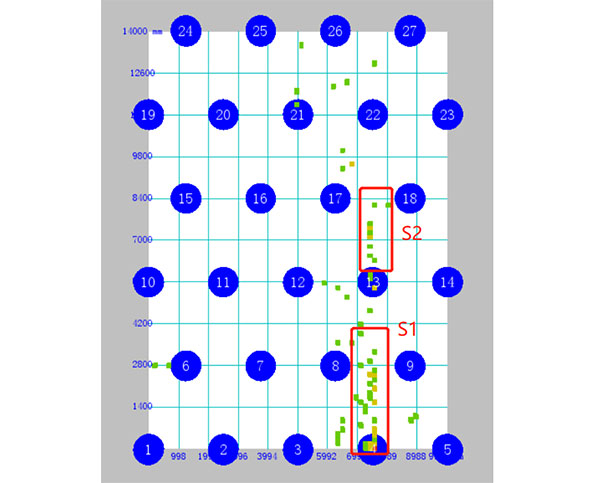

-

SWAE software views: data table, parameter correlation views, location view.

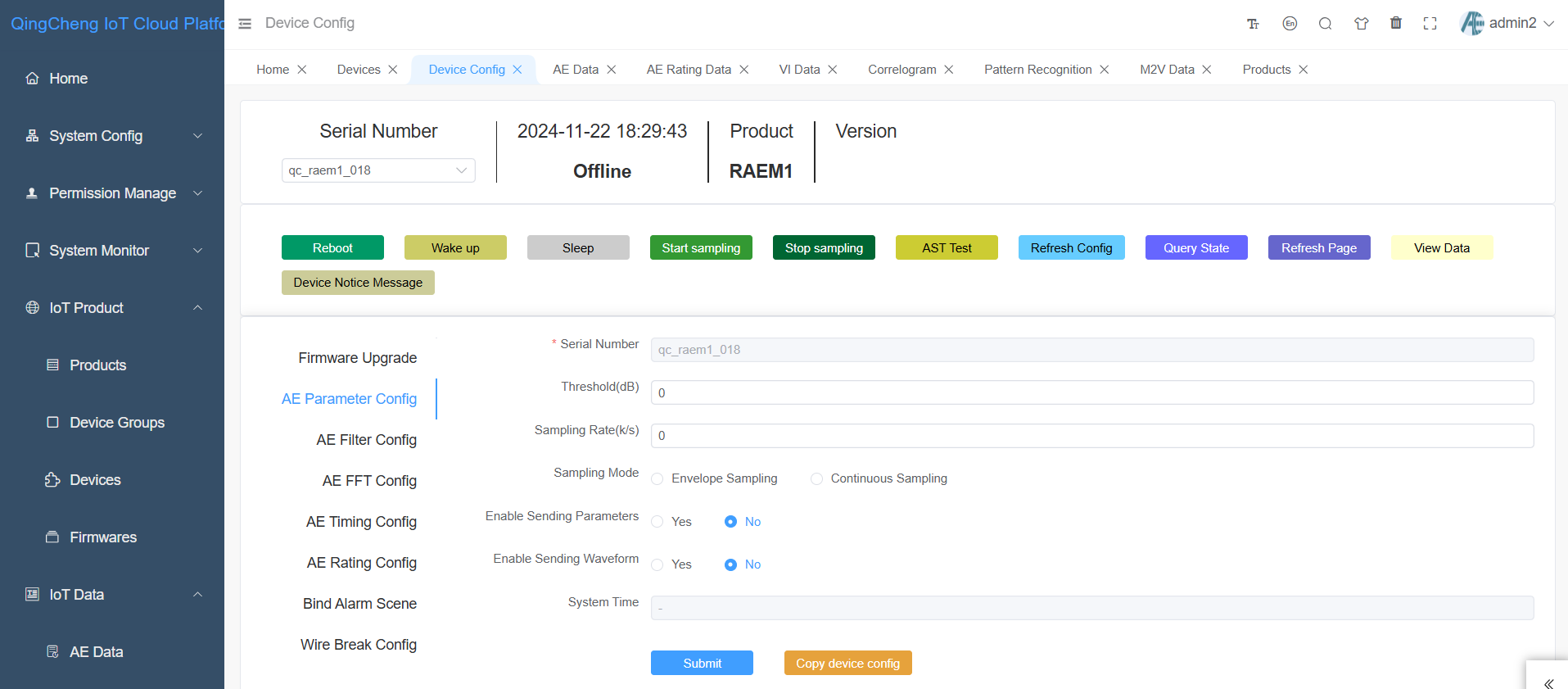

- Qingcheng IoT Cloud Platform display waveform, various parameters, result rating levels, and device remote configurations.

Further Information

Contact Form

Please complete the form below to request your quote. We will be in contact as soon as possible.