Tool Condition Monitoring System

Using Acoustic Wave (Acoustic Emission)

Application

Acoustic emission technology is used on machine tool condition monitoring or cutting tool condition monitoring. The RAEM2 wireless tool condition monitoring system can extends tool life and eliminates workpiece damage caused by tool wear.

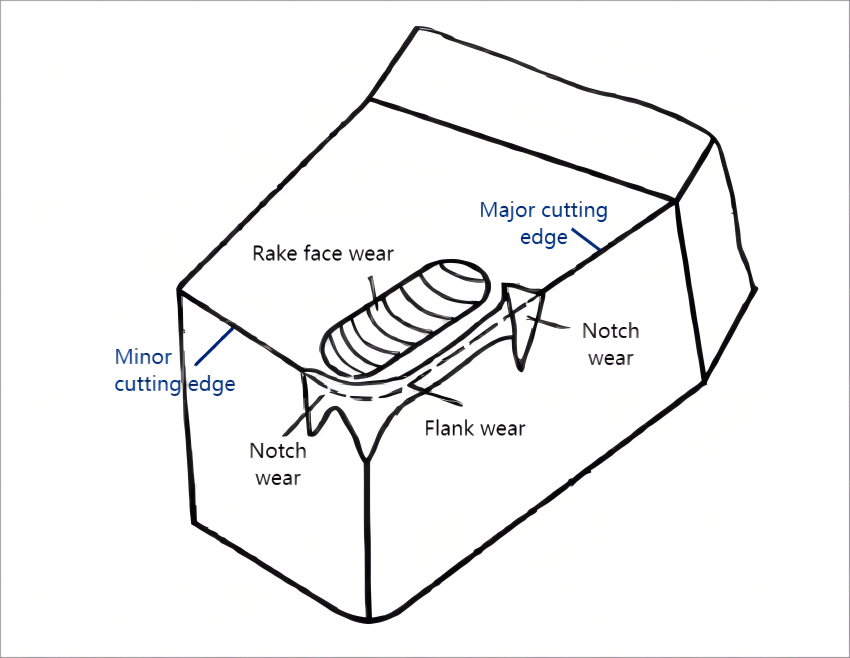

In the process of turning, milling, grinding, punching, drilling and more cutting tool machinery, there may be plastic deformation of the workpiece, wear caused by the friction between the tool and the workpiece or chip, chip fracture and tool fracture.

Cutting tool wear modules

Principle

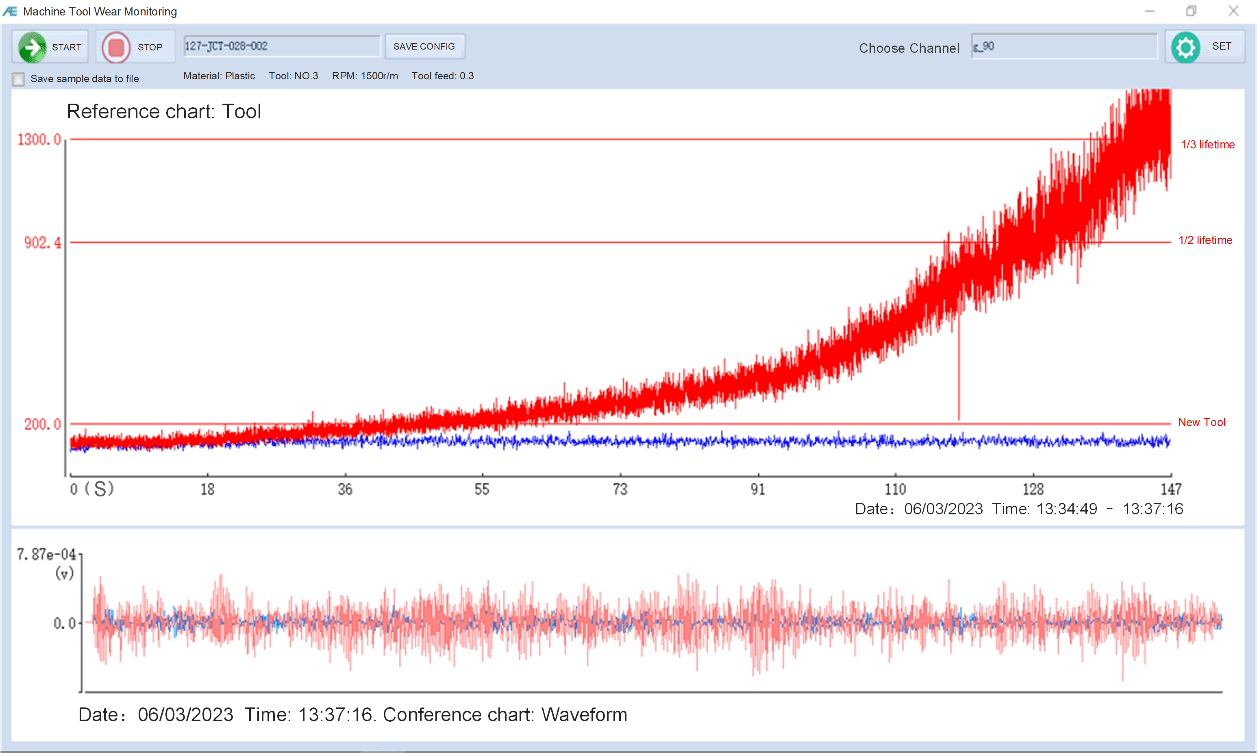

The acoustic signal from the machining process reflects the tool wear condition. The monitoring system receives the acoustic signal and analyzes the tool wear condition.

Application Results

- All year round of online monitoring and detection

- The whole process of automatic analysis results

- Internet of Things remote operation and use

- Real-time mobile phone alarm notifications

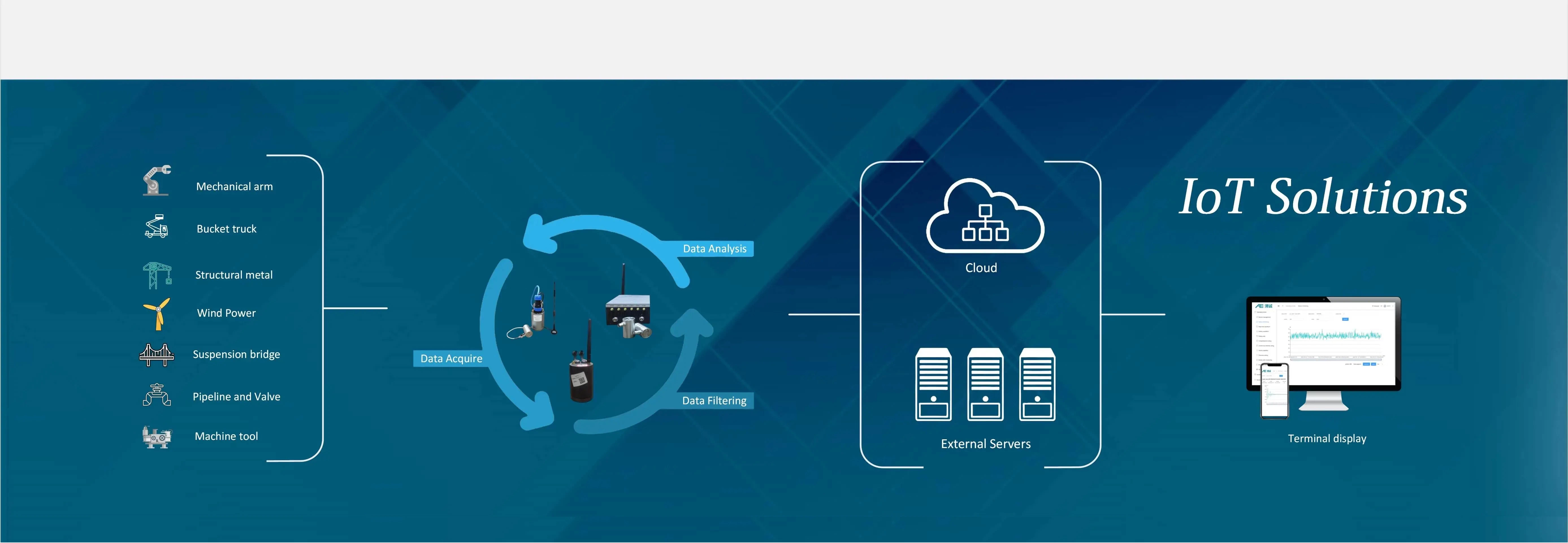

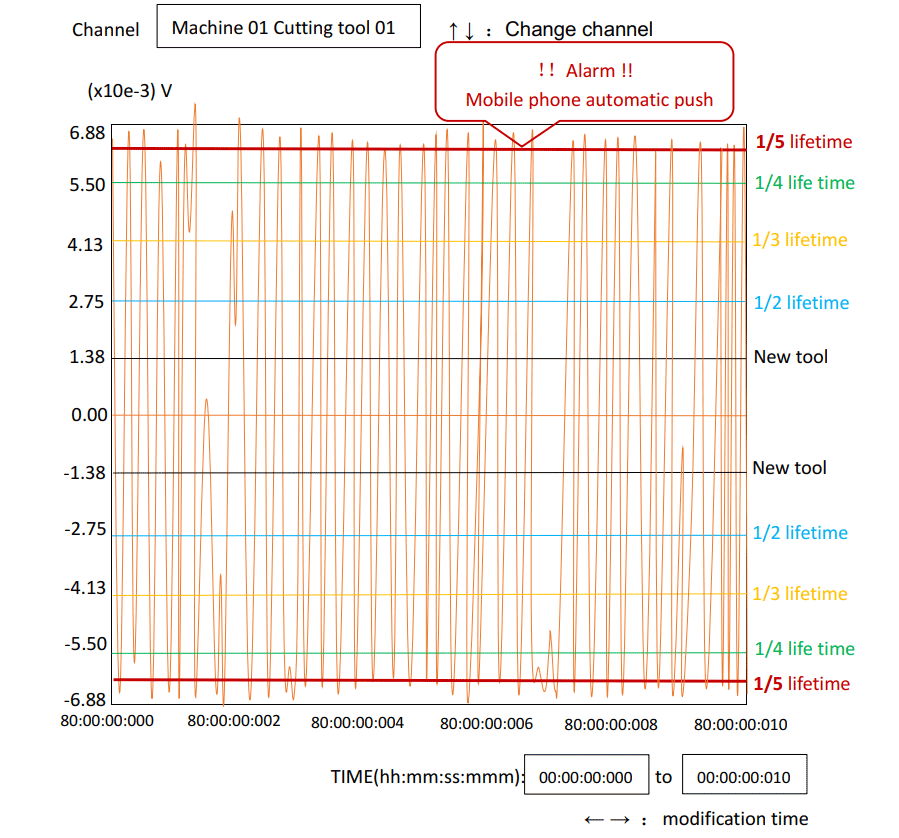

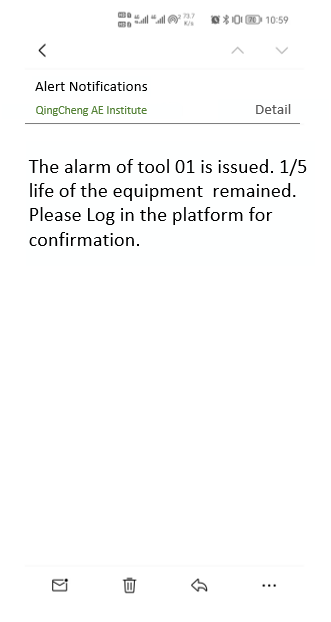

Fig. 1 Diagram of cloud platform

Fig. 2 Diagram of alarm information

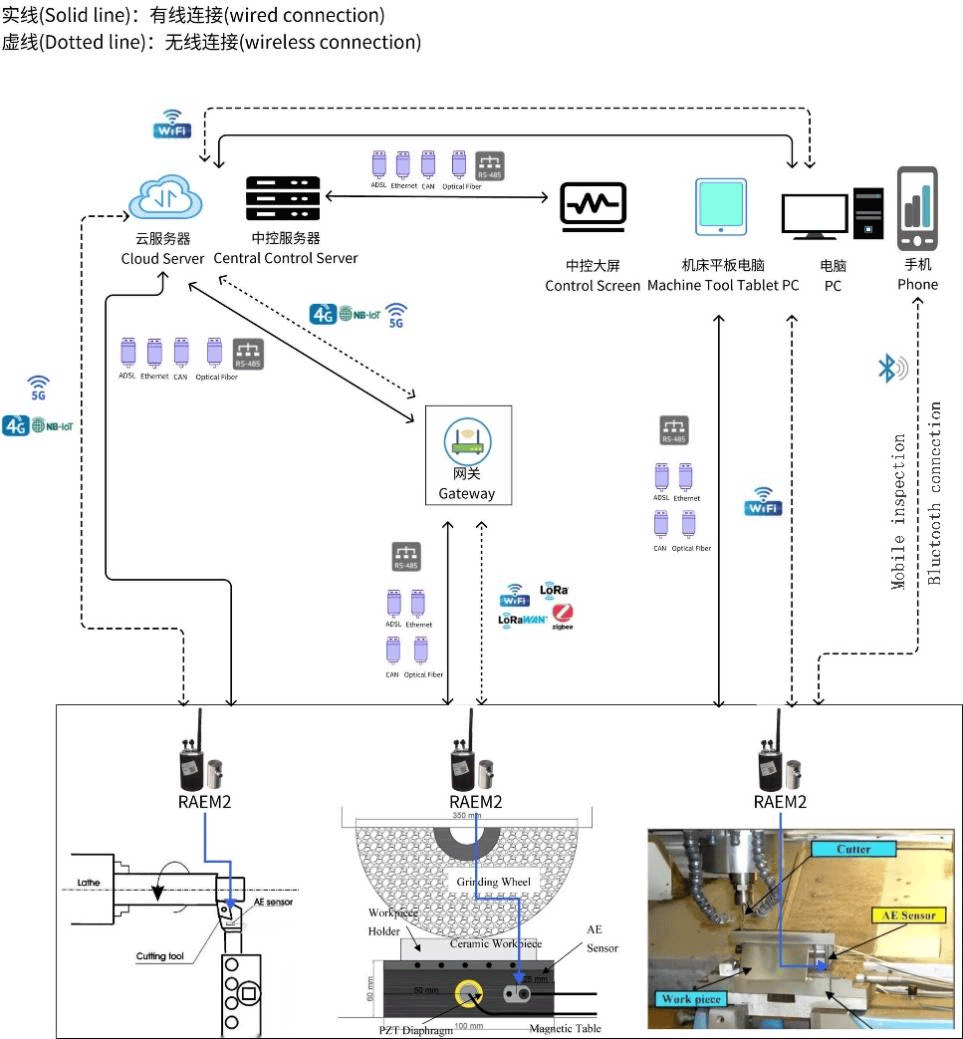

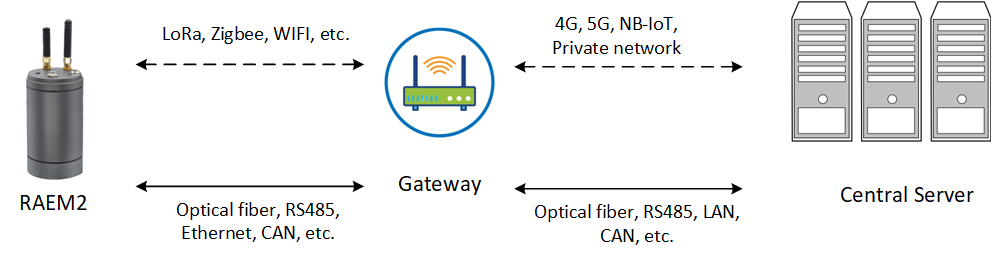

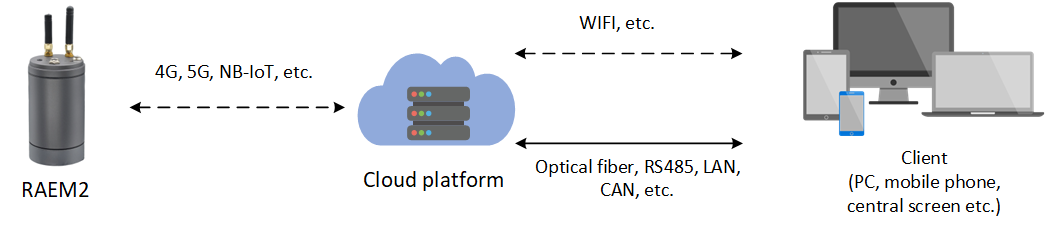

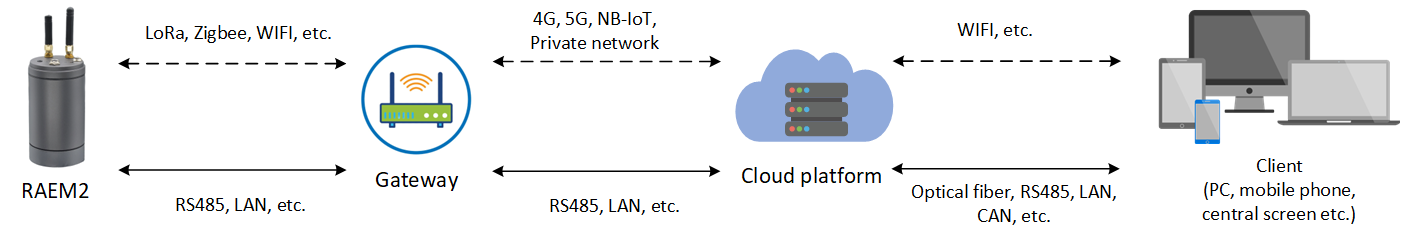

RAEM2 Series Remote AE Monitoring System Diagram

Four Data Communication Methods:

1)Onsite operation and display:

2)Control room operation and display

3)Remote network direct communication system

4)Remote networking communication system:

Note: The above systems have the mobile phone app with Bluetooth communication functions for patrol inspection and field debugging settings.

Main Hardware and Software Introduction

RAEM2 series Remote Acoustic Emission Monitoring System consists of:

-

RAEM2

- Sensor

- Acquisition

- Communication modules

- Cloud platform

- Client terminals

1.1 Sensor

W500, GI40 or GI150 series sensors can be used. AE sensors can convert acoustic waves mechanical signals into electrical signals and transmit signals to acoustic emission acquisition and analysis system.

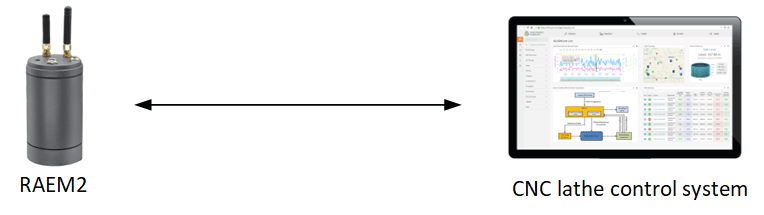

1.2 RAEM2

RAEM2 AE system integrates sensor, acquisition board, data communication (Bluetooth, etc.) and battery power supply.

1.3 Cloud platform

Qingcheng IoT cloud platform, Ali Cloud platform, Amazon cloud platform, etc.

Real-time data display: users can carry out remote monitoring through the cloud platform and the cloud platform can push alarm information to users automatically when the device is abnormal.

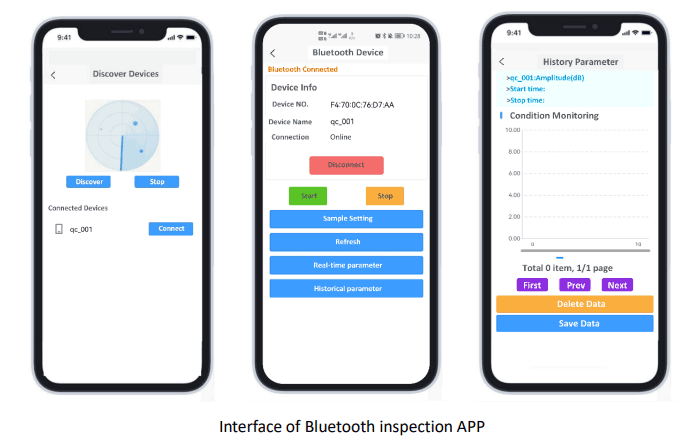

1.4 Bluetooth App Patrol

This system supports onsite inspection by connecting devices with smart phone via Bluetooth for device Settings and data monitoring.

Further Information

Contact Form

Please complete the form below to request your quote. We will be in contact as soon as possible.