Aboveground Storage Tank (AST) Bottom Plate Corrosion Detection/ Monitoring

- Solutions

- Data Analysis

- User Cases

- Materials

1. Conventional AE Tank Corrosion Detection Scheme

Principle

When there are corrosion defects on the bottom plate of the storage tank, the corrosion products will peel off and fall off, generating acoustic emission signals; when the bottom plate leaks, the medium flows and generates acoustic emission signals. The sensor array at the bottom of the tank wall receives the signal, and the acoustic emission acquisition instrument processes and analyzes the signal to evaluate the corrosion status of the tank bottom structure.

System Composition

Acoustic emission sensor, preamplifier, acoustic emission acquisition instrument, computer software.

|

|

| Device module | SAEU3H Multi-channel AE detection system |

| Operation system | Windows |

| Channels | Multi-channel, cascadable to 100+ channels |

| Acoustic emission sensors |

GI40/ G40 for tank bottom corrosion; GI150 for tank body cracks |

| Sampling rate | 10M/s, 16-bit |

| Waveform collection | Support |

| Analog filters |

High-pass filters: 20kHz, 100kHz, 400kHz; Low-pass filters: 100kHz, 400kHz, 1200kHz |

| Digital filters | 1KHz-2.5MHz |

| Dimensions |

4-channel chassis: 320mm × 125mm × 50mm; (Length x Width x Height) 20-channel chassis: 308mm × 225mm × 133mm; (Length x Width x Height) 48-channel chassis: 308mm × 368mm × 133mm; (Length x Width x Height) |

| Advantages | USB3.0 high-speed data transmission, good expansion ability, stable performance, accurate defect location function. Suitable for regular detection. |

SWAE acoustic emission system software is a combination of real-time acquisition and analysis and post-analysis software. It supports two types of AE product series, SAEU3H instrument and RAEM1 series (RAEM1 and RAEM1-6) respectively. SWAE can perform data acquisition, playback and analysis on the equipment. Its main functions are location map, correlation graphs, data table, and frequency domain waveform map, etc.

Xingsan Joint Station Case: online detection of AE from storage tanks

Sensor Arrangement

For example, nine sensors were evenly arranged around the outer wall about 50 cm above the bottom plate, avoiding discontinuous locations such as pipes and manholes as much as possible, with a horizontal spacing of about 7.8 meters.

Fig 1.1 Sensor Arrangement

Data Collection and Analysis

Acoustic emission testing of the tank for 2 hours:

Fig 1.2 Tank #2 Channel - Hits Correlation Graph

Fig 1.3 Tank #2 Arrival time - Energy Correlation Graph

Fig 1.4 Tank #2 TDOA Location Map for 2h

Fig 1.5 Location Map when Pressure Maintaining

Test Results

According to Section 9.2 of the standard “JB/T 10764-2023”, the time difference location analysis and classification methods of the tank bottom acoustic emission source were adopted. The length of 10% of the diameter was used to delineate a circular assessment area. Perform local analysis on all location sources with relatively concentrated events within the evaluation area and calculate the number of location events E per hour. According to Figure 1.5, three were 173 effective events during pressure maintenance and there were 3 relatively concentrated locating areas, defined as S1, S2, and S3.

S1: E1=7; S2: E2=10; S3: E3=4.

The reference event number per hour criterion was set as a=10, based on experiences results using the same testing equipment and settings under the same environment. Considering the liquid level height during pressure maintenance and the comprehensive acoustic emission characteristic parameters, the classification result was Level I, which means “there are no signs of local corrosion, and the corrosion condition is minimal”. The repairing suggestion: do not consider repair. It is recommended to conduct acoustic emission testing again within 6 years or open the tank at an appropriate time to observe the dynamic changes of corrosion on the tank bottom plate.

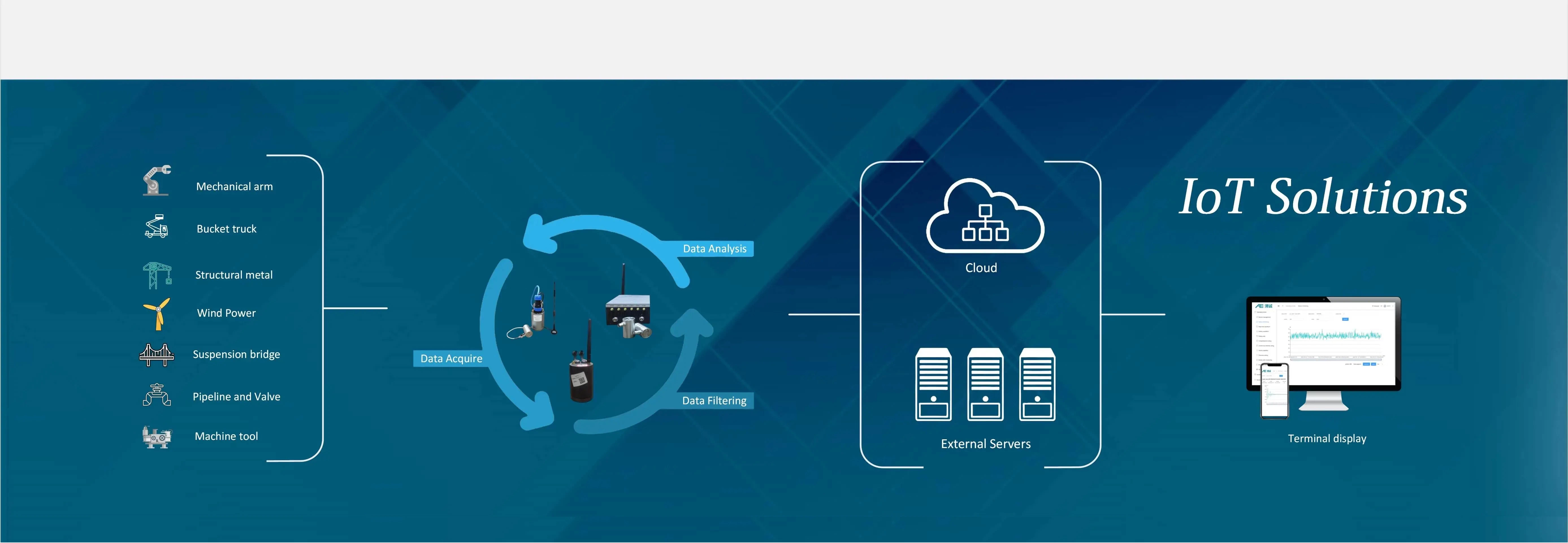

2. IoT Acoustic Emission Wireless Online Monitoring Solutions

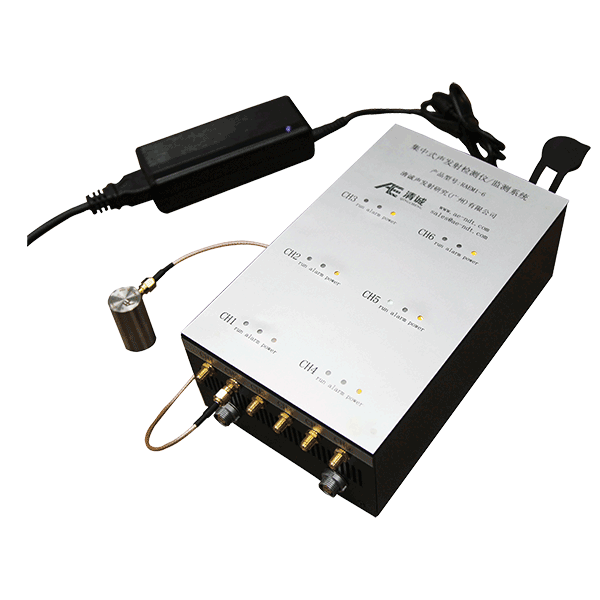

2.1 Centralized Solution Based on RAEM1-6

Principle

When corrosion defects or leakage occur on the bottom plate of the storage tank, acoustic emission waves are generated. The sensors receive the acoustic waves, which are then processed and analyzed by the acoustic emission acquisition unit. The result signals are transmitted to the cloud server through a 4G/WiFi network, and users log in to the cloud platform (private cloud/Qingcheng cloud) to remotely view the data and set rating criteria. The system automatically provides rating results based on the criteria. Once the alarm threshold is reached, an alarm is automatically pushed.

System Composition

Acoustic emission sensors, acoustic emission acquisition instrument (signal acquisition and analysis and communication), cloud servers (cloud server IoT platform/LAN server/computer/mobile phone, etc.), customer terminals (mobile phone, PC, etc.).

|

|

| Device module | RAEM1-6 Multi-channel AE system |

| Operation system | Linux |

| Channels | 6 channels, can be cascaded to 100+ channels |

| Acoustic emission sensors |

GI40/ G40 for tank bottom corrosion; GI150 for tank body cracks |

| Sampling rate | 2M/s, 16-bit |

| Waveform collection | Support |

| Analog filters |

High-pass filters: 30kHz, 125kHz; Low-pass filters: 80kHz, 175kHz |

| Digital filters | 1KHz-1.0MHz |

| Communications | WiFi/ 4G |

| Dimensions | Length x Width x Height: 22cm × 13cm × 8cm |

| Advantages | Based on the Linux operating system, it has stable performance, wireless communication capability, and is suitable for long-term remote unmanned monitoring. The devices can be cascaded to form a large-scale monitoring system. |

2.2 Distributed Solution Based on RAEM1

Principle

When corrosion defects or leakage occur on the bottom plate of the storage tank, acoustic waves (acoustic emission) are generated. The acoustic emission acquisition unit receives the signals, processes and analyzes them, and transmits them to the cloud server through a 4G/WiFi/LAN network. Users log in to the cloud platform (private cloud/Qingcheng cloud) to remotely view data and set rating criteria. The system automatically gives rating results based on the criteria. Once the alarm threshold is reached, an alarm is automatically pushed.

System Composition

Acoustic emission acquisition unit (sensors, signal acquisition and analysis, communication), cloud server (cloud server IoT platform/LAN server/computer/mobile phone, etc.), client terminal (mobile phone, PC, etc.).

|

|

| Device Module | RAEM1 |

| Operation system | Linux |

| Channels | Single channel |

| Acoustic emission sensors |

GI40/ G40 for tank bottom corrosion; GI150 for tank body cracks |

| Sampling rate | 2M/s, 16-bit |

| Waveform collection | Support |

| Analog filters |

High-pass filters: 30kHz, 125kHz; Low-pass filters: 80kHz, 175kHz |

| Digital filters | 1KHz-1.0MHz |

| Communication | WiFi/ 4G/ RS-485 |

| Advantages | RAEM1 has built-in sensors, signal acquisition, signal processing, data transmission, battery power supply, and wireless clock synchronization. Its strong magnetic bottom can be directly attached to the metal tank wall during installation. Generally applicable to metal storage tanks, it can be remotely monitored without human intervention or can do the traditional AE testing on-site. |

2.3 Chained Solution Based on RAEM1

Principle

When corrosion defects or leakage occur on the bottom plate of the storage tank, acoustic waves (acoustic emission) are generated. The acoustic emission acquisition unit receives the signals, processes and analyzes them, and transmits them to the cloud server through the PoE router. Users log in to the cloud platform (private cloud/Qingcheng cloud) to remotely view data and set rating criteria. The system automatically gives rating results based on the criteria. Once the alarm threshold is reached, an alarm is automatically pushed.

System Composition

Acoustic emission acquisition unit (sensors, signal acquisition and analysis), router, cloud server (cloud server IoT platform/LAN server/computer/mobile phone, etc.), client terminal (mobile phone, PC, etc.).

|

|

| Device Module | BWM1 |

| Channels | Single channel; multiple channels in series connection |

| Acoustic emission sensors |

GI40/ G40 for tank bottom corrosion; GI150 for tank body cracks |

| Sampling rate | 2M/s, 16-bit |

| Waveform collection | Support |

| Analog filters |

High-pass filters: 30kHz, 125kHz; Low-pass filters: 80kHz, 175kHz |

| Digital filters | 256-order FIR filter, any pass-through, high-pass, low-pass and band-pass settable from 0kHz-1000kHz |

| Communication | Ethernet |

| Dimension | 507*50*43mm (waterproof plug included) |

| Advantages | The layout of this scheme is in chain series connection. The chain connection refers to the AE acquisition units are connected in series via PoE using Ethernet cables. Data transmission and power supply are both achieved through PoE, simplifying the wiring needs. |

IIoT Wireless Online Monitoring System Acquisition Work Flow

Cloud Computing Process Work Flow

QC Cloud Main Functions

Cloud platform remote parameter settings: acquisition mode, threshold, sampling rate, filtering range, HDT, HLT, EET and other parameters.

Cloud platform data display: real-time/historical (parameter/ waveform) data, rating results, parameter comparison results display.

Automatic alarm notifications: Alarm information is pushed to the clients through SMS, emails, and other methods.

Automatic report generation: After filling in relevant information through the cloud platform, the system automatically generates a report. And download the report from the cloud platform with one clicking.

Case Study

①The test data results of 6 storage tanks of the same size and medium under the same usage conditions, with a pressure holding time of 1 hour, are shown in the table:

| Tank 1 | Tank 2 | Tank 3 | Tank 4 | Tank 5 | Tank 6 | |

| Total Hits | 20348 | 868 | 9617 | 203876 | 8984 | 968 |

| Total Events | 2340 | 178 | 239 | 25600 | 268 | 180 |

| Max Hits | 7834 | 378 | 3000 | 68876 | 3400 | 420 |

| Min Hits | 456 | 360 | 333 | 321 | 487 | 365 |

| Corrosion Level | III | I | II | IV | II | I |

| Corrosion Status | There are obvious signs of localized corrosion. | No signs of localized corrosion. | There are slight signs of localized corrosion present. | There are signs of severe localized corrosion. | There are slight signs of localized corrosion present. | No signs of localized corrosion. |

| Maintenance Suggestion | Consider maintenance | No maintenance required | No need to consider maintenance in the near future | Prioritize maintenance as the top priority | No need to consider maintenance in the near future | No maintenance required |

According to Section 9 of the standard ‘JB/T 10764-2023 Non destructive Testing - Acoustic Emission Testing and Evaluation Method for Atmospheric Pressure Metal Storage Tanks’, the classification of acoustic emission sources based on cluster zone analysis for tank bottom plates in Table 3 was that K=500 (Hits per hour for an independent channel). Obtained the detailed classification levels of each storage tank as shown in the table above.

Based on the review of historical operation records and other data of storage tanks, it was determined that tank #2 and #6 were intact tanks (Level I) and do not require maintenance; Tank #4 was a tank with severe corrosion of its bottom plate (greater than Level III) and requires the highest priority for maintenance. The same method can be used to perform the same tank level analysis on the entire process of tank loading and the specific processes of pressure rise and maintenance.

1.Cloud Platform Display

Users can configure and monitor remotely through the cloud platform, and upload data to the cloud platform for display and analysis.

Figure 1: Channel 1 of Tank 4 (RAEM1_TJSH-001) system rating levels from the 3rd, 6th, 9th, 12th, 15th, and 18th months, which are level I, I, I, II, II, III respectively.

2.Mobile Phone Notifications

When the alarm limit is reached, the phone pushes the alarm notifications. Alarm methods: Mini program, email, SMS, APP.

According to the data of Tank 4 on the cloud platform, significant corrosion (Level III) was observed during the 6th monitoring. The mobile phone synchronously receives alarm notifications, including information such as tank level, status, and repair suggestions.

3.SWAE Software

After downloading data from the cloud, in-depth analysis can be conducted using Qingcheng's SWAE software, or it can be directly sent to SWAE software for real-time analysis and processing.

Case: Data from holding pressure for 1 hour.

Total number of hits: 10617, maximum 3000 (Channel 1), minimum 333 (Channel 7), total event number: 239. There is slight localized corrosion. Through Qingcheng's SWAE software, data can be viewed and corrosion sites can be located.

Tank bottom location map (time difference location)

Channel - hits correlation graph (zone location)

Automatic detection and rating, remote viewing, proactive alarm push, in compliance with standards:

- Automatically detect and obtain data according to the set time. After setting the K value according to the standard content, the K value can be used as an automatic rating criterion for automatic data processing, and the corrosion status level of each storage tank required by the standard content can be automatically analyzed.

- The corrosion status level and specific data of the storage tank can be accessed anytime on the cloud IoT platform through computers and mobiles at any location.

- Setting the alarm level, such as Level III alarm, will automatically push the alarm notifications to the designated mobile phone number after 18 months of detection in the above case, reminding them to take immediate measures such as opening the can for inspection.

User Cases

Accidents of tank bottom plate thinning and perforation leakage due to corrosion occur from time to time. According to statistics, tank failures caused by corrosion account for over 60% of all tank failures. Adopting effective tank inspection methods is of great significance for safety production, resource conservation, and environmental protection.

1)Application Case of Acoustic Emission Testing in CUPET Tank Bottom Inspection Training

From March 6th to March 12th, 2017, in the oil tank area of Matanzas Port in Cuba, testing was conducted in accordance with the Chinese machinery industry standard "JB/T 10764-2007 Atmospheric Pressure Metal Storage Tank Acoustic Emission Testing and Evaluation Method".

In the past month, the loading history shows that the highest liquid level has reached 10.6 meters, and the planned liquid level for this test will rise to 10.8 meters. According to the circumference design of the probe position, the actual number of channels used is 29, and the sensor spacing is about 8 meters. Finally, a comprehensive inspection was conducted on the storage tank group of the Cuban National Oil Company. Based on the distribution of hit numbers, a specific implementation plan for inspection of opening the tank has been determined, and the qualification standards for subsequent annual inspections have been formulated based on the results of the open tank.

2)Acoustic emission detection of storage tanks in Zhongyuan Oil field

Entrusted by the Oil and Gas Storage and Transportation Management Office of Zhongyuan Oil field, our company conducted acoustic (acoustic emission) inspection on the 20000m3 storage tank of Zhongyuan Oil field in August 2006.

Storage Tank Exterior

Sensor Installation

Preamplifier

Acquisition system

4)Special Oil Company's Special One Joint Station Tank Acoustic Emission Online Detection

The storage tank is an external arch roof tank with a capacity of 10000 cubic meters, a diameter of 27.75 meters, an effective height of 14.8 meters, and a storage medium of crude oil. The safe liquid level is 12.5 meters, and the initial liquid level detected is 17.8 meters. The tank wall is coated with anti-corrosion paint and has insulation boards and metal sheet metal protective plates.

Installation diagram of on-site sensor section

Channel - Hits Correlation Graph

Time - Energy Diagram

Time Difference Location Map

Contact Form

Please complete the form below to request your quote. We will be in contact as soon as possible.