Your position:HOME > Online Monitoring Solutions

Vibration (V) and Acoustic Emission (AE)

Similarity:

Measure mechanical waves.

In fact, Acoustic Emission (AE) is sometimes simply described as the next generation of vibration techniques. - See an article in reliable plant: here as an example.

Differences:

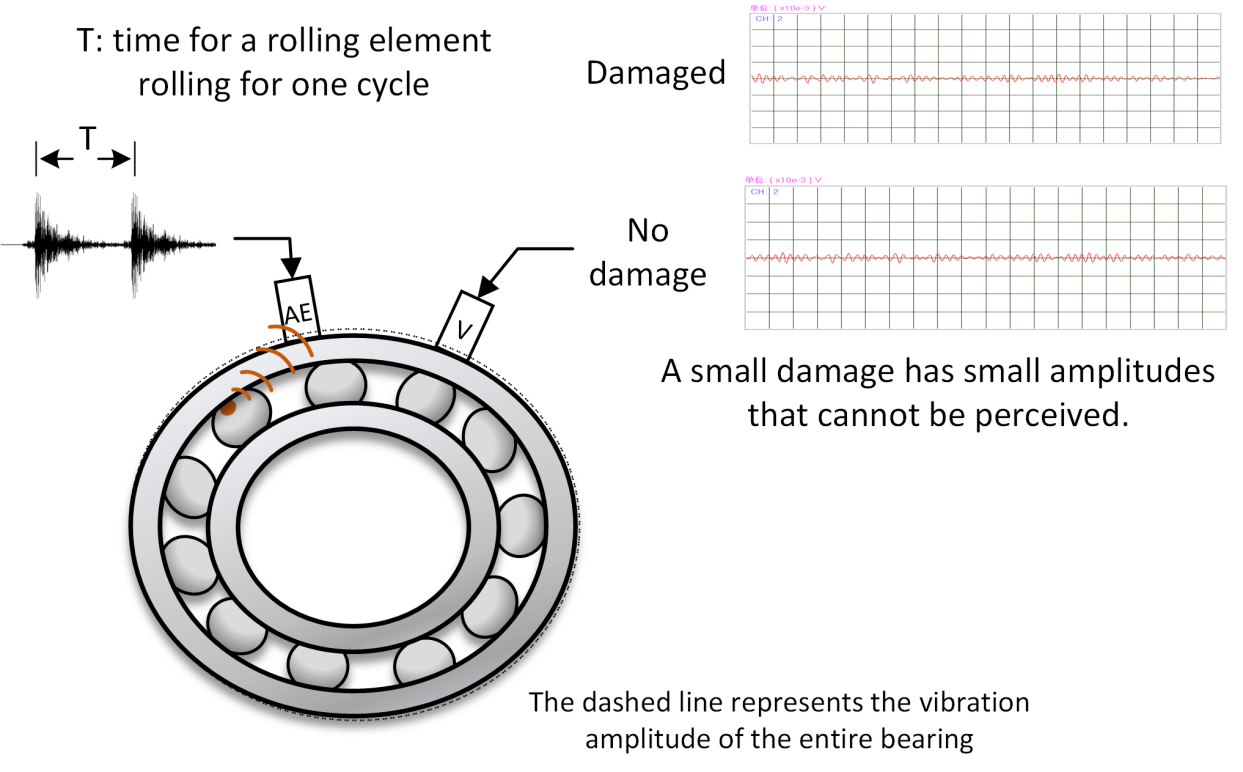

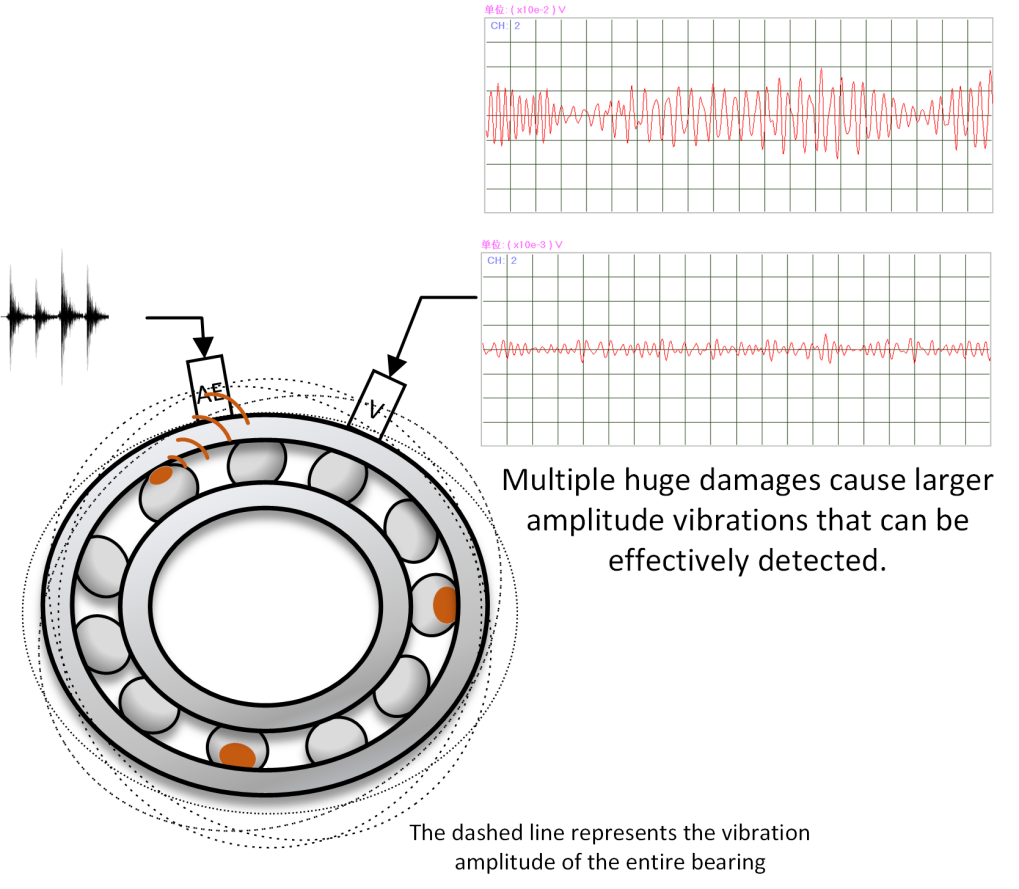

1.Vibration sensor: detect the overall vibration of the structure, which is s steady state signal.

2.Acoustic emission sensor: detect the acoustic waves from the local acoustic source, which can be transient signals and steady state signals.

Figure 1. V & AE: Single small damage with small amplitude vibration and multiple huge damages with large amplitude vibration of bearings

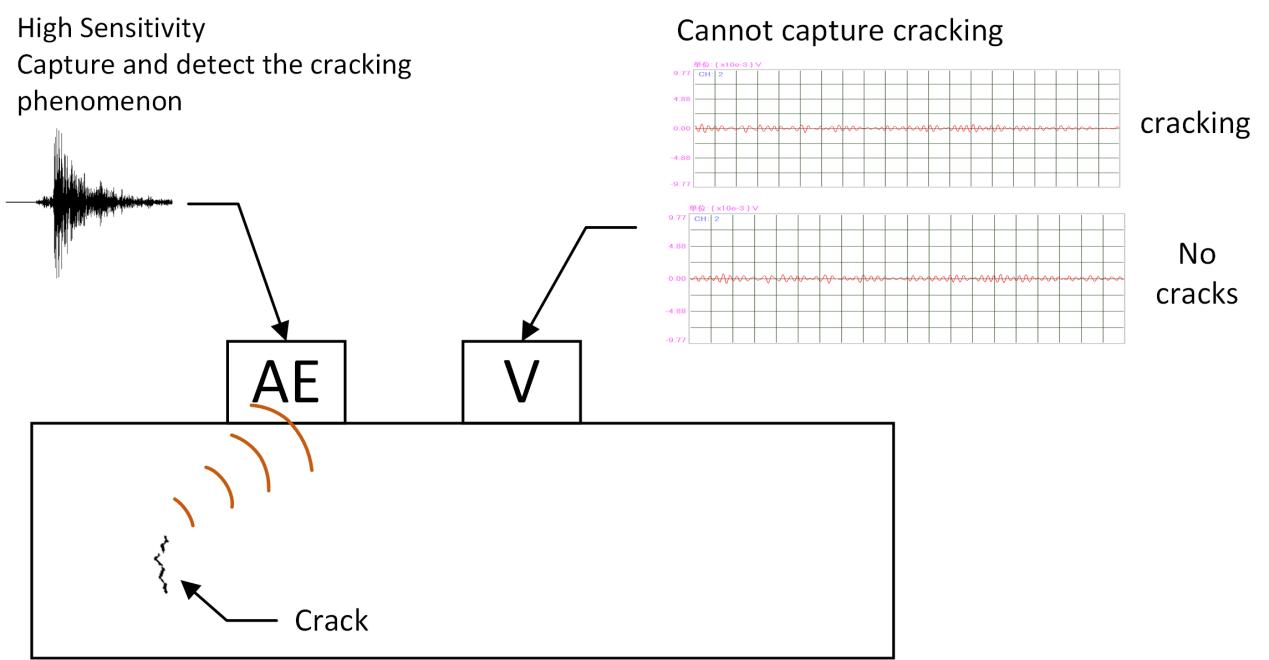

Figure 2. V & AE: Crack signals, which can be captured by AE but not by V

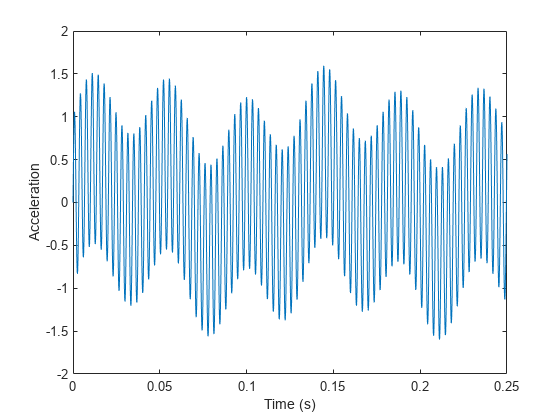

Figure 3. Vibration signal: low frequency continuous wave at low sampling rate

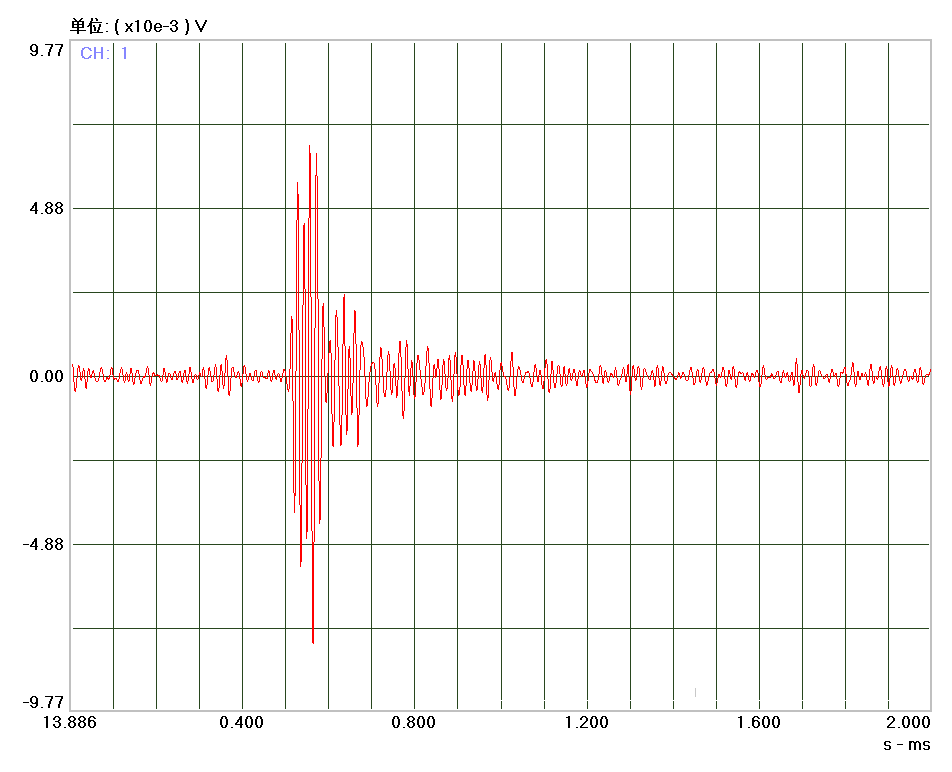

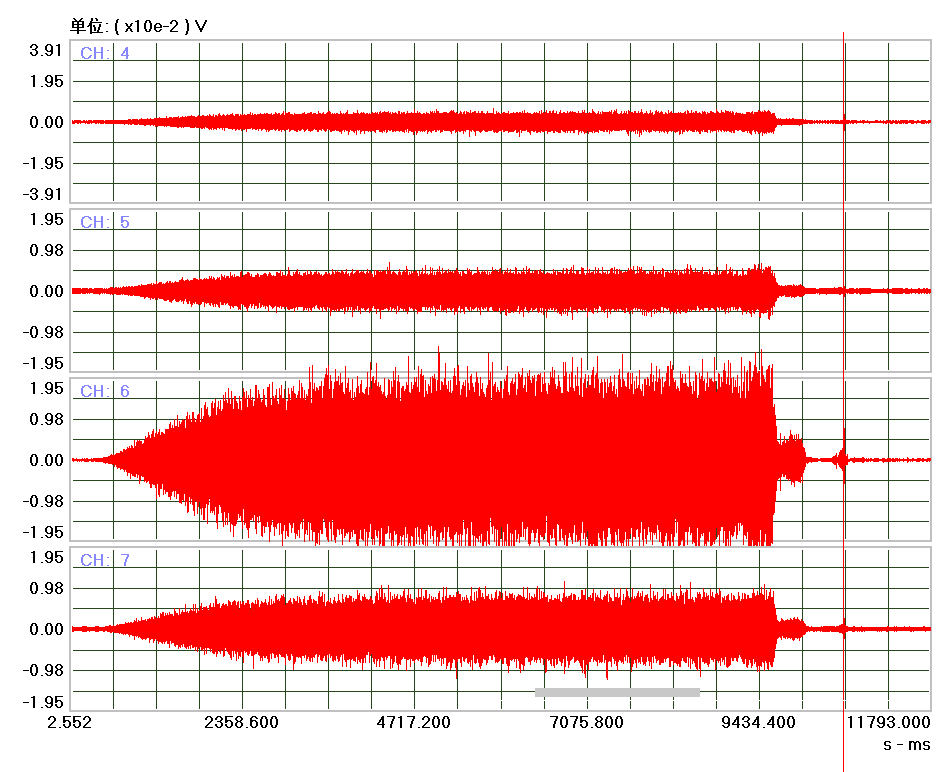

Figure 4. AE signal: high frequency pulse waves and continuous waves at high sampling rate

Application Features of Vibration Detection:

- Vibration monitoring is applicable to condition monitoring and fault diagnosis of steady-state signals, such as condition monitoring and fault diagnosis of rotating machinery. The data is stable and not susceptible to environmental mechanical wave interference.

- Vibration detection does not detect surface waves. The sensors don’t have to contact with the surface of the detection object (such as MEMS sensors on circuit boards), and the sensor surface can be free of acoustic coupling agents.

- The collection of low frequency signals contains a small amount of data and the detection equipment cost is low.

- Vibration detection does not capture transient mechanical waves so it cannot detect transient states and faults such as cracks.

- Vibration detection detects the entire object and is not sensitive or even unable to detect local states and faults, such as minor damages and wear.

Application Features of acoustic Wave (Acoustic Emission) Detection:

- Acoustic emission (AE) detection is suitable for state monitoring and fault diagnosis of both transient and steady-state signals, such as transient signals of crack initialization and steady-state signals from the state monitoring and fault diagnosis of rotating machinery. Transient signal detection is vulnerable to environmental mechanical wave interference, such as raindrops or small particle collision. The data is stable during the steady state signal detection, and is not vulnerable to environmental mechanical wave interference.

- Acoustic wave (acoustic emission) detection detects surface waves, and the sensor must be in contact with the surface of the detection object.

- The collection of high frequency signals contains a large amount of data and the cost of the detection equipment is high.

- Acoustic wave (acoustic emission) detection captures transient mechanical waves so it can detect transient states and faults such as crack initialization.

- Acoustic wave (acoustic emission) detects local acoustic source signals and it is highly sensitive to local states and local damages such as small wear and tears, cracks. So it can detect early stage faults and damages.