Your position:HOME > Online Monitoring Solutions

Vibration Testing and Acoustic Wave (Acoustic Emission) Testing

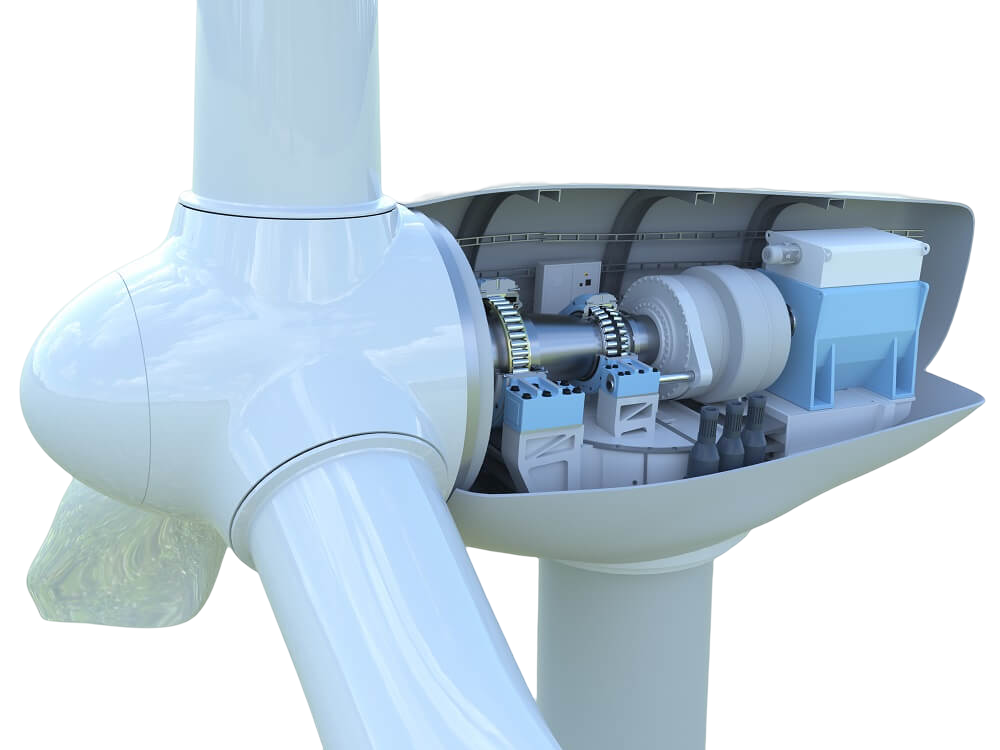

Both vibration testing and acoustic wave (acoustic emission) testing are commonly used for condition monitoring, such as rotating machinery, machined parts, etc. What's the difference between the vibration testing and acoustic emission (AE) testing?

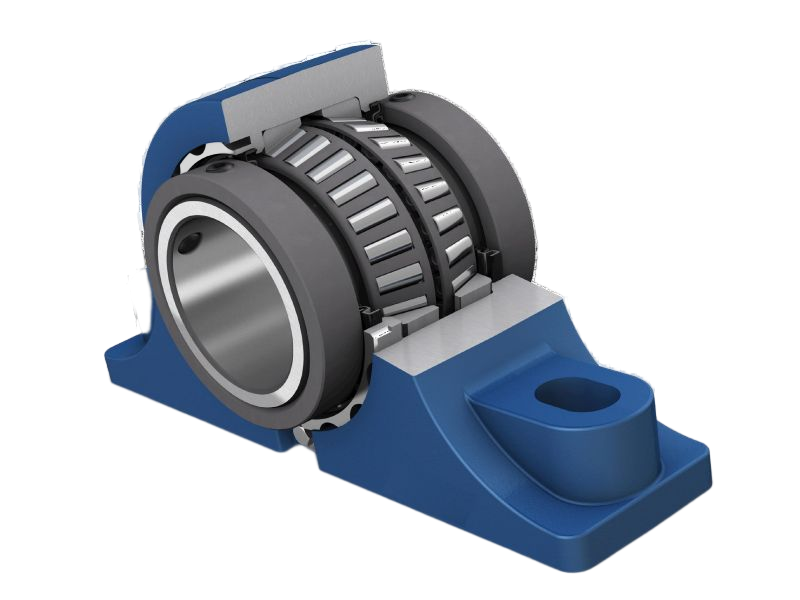

Rotating mechanical drawing

Machined parts

In fact, Acoustic Emission (AE) is sometimes simply described as the next generation of vibration techniques. - See an article in reliable plant: here as an example.

1.Different Testing Principles

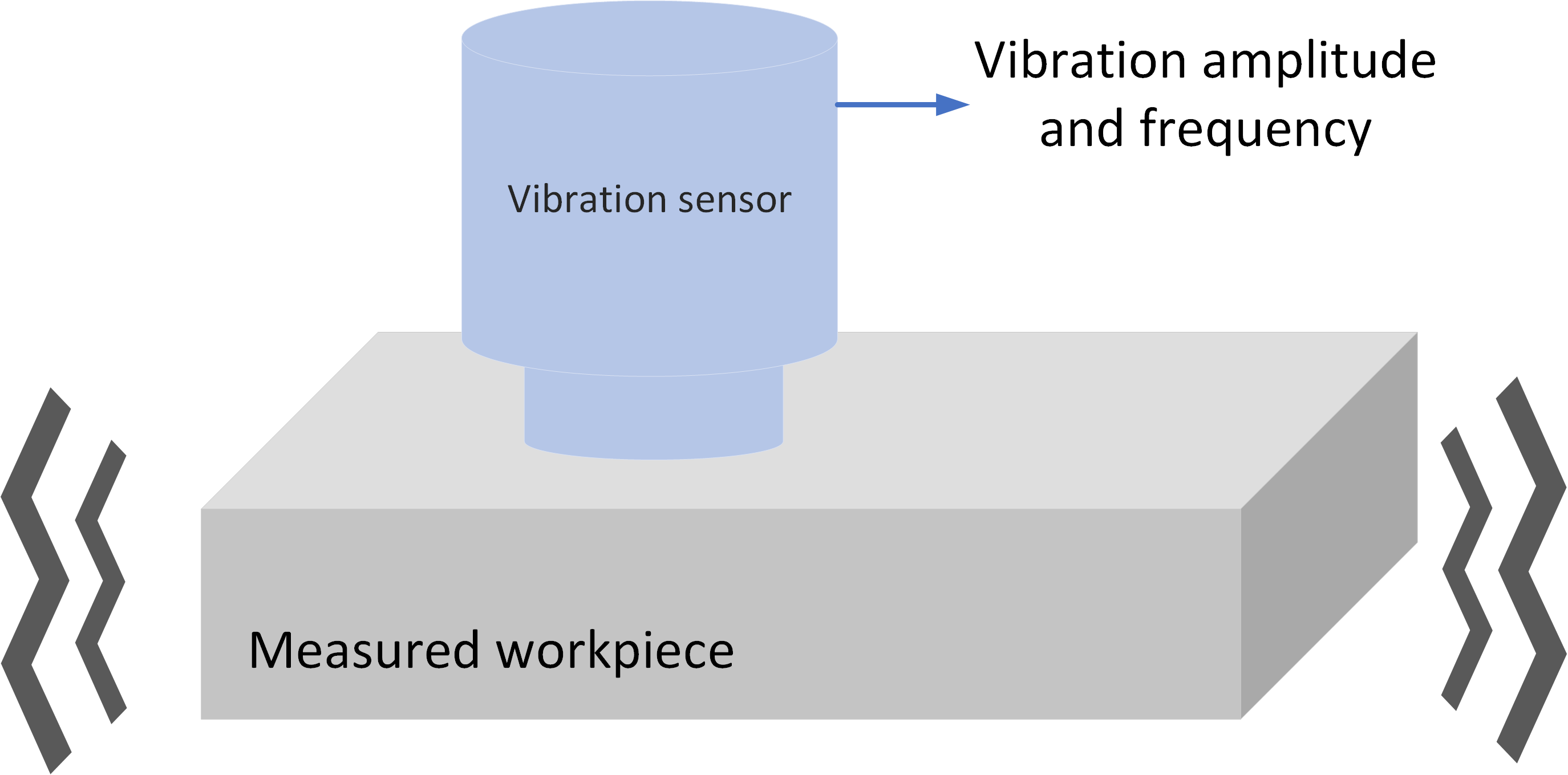

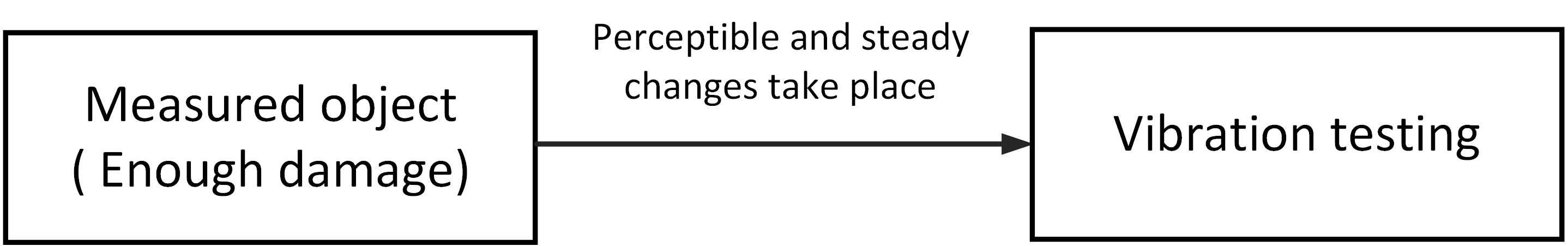

Vibration testing is to test the vibration phenomenon of the measured object, that is, the vibration amplitude and frequency of the whole measured object.

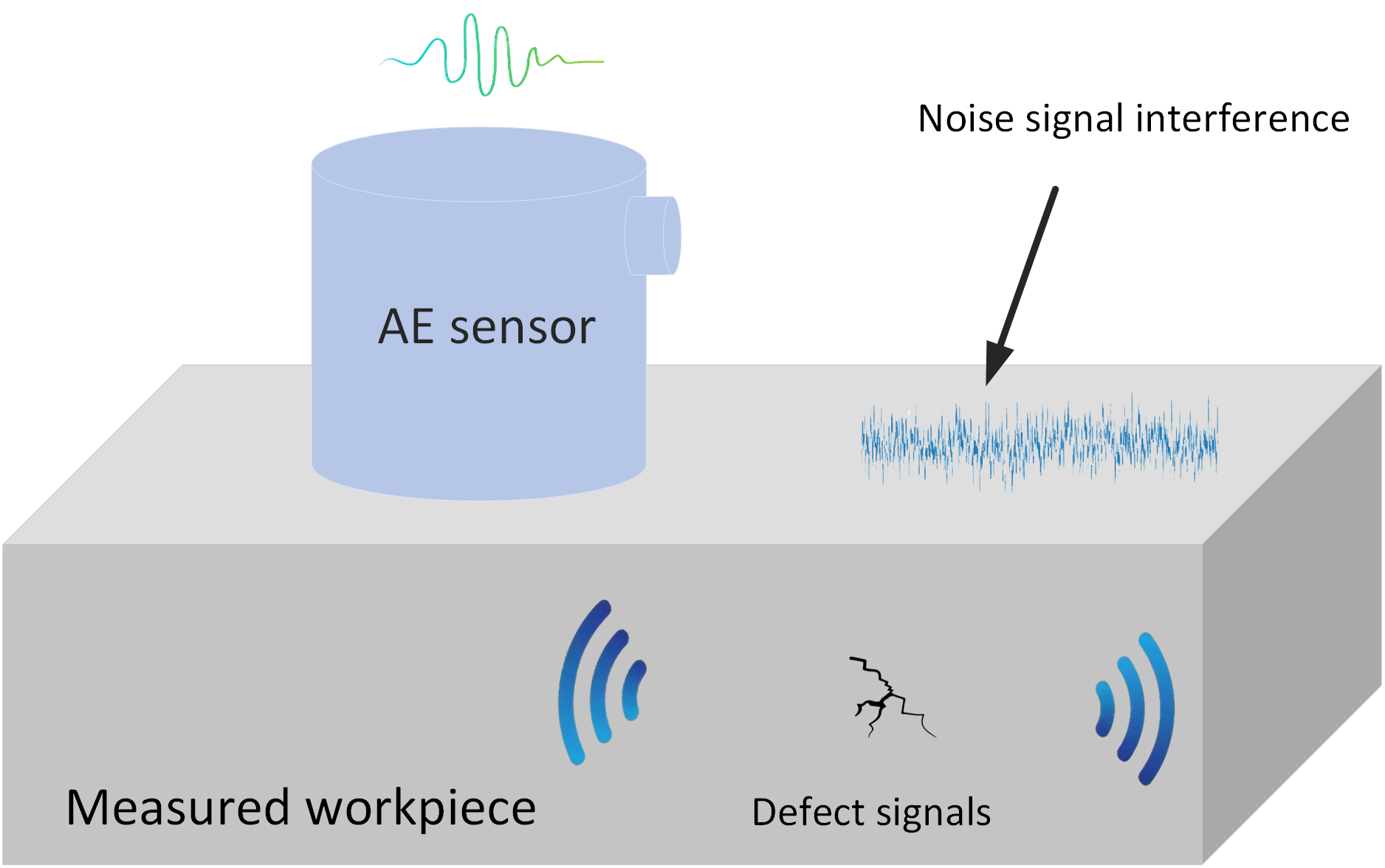

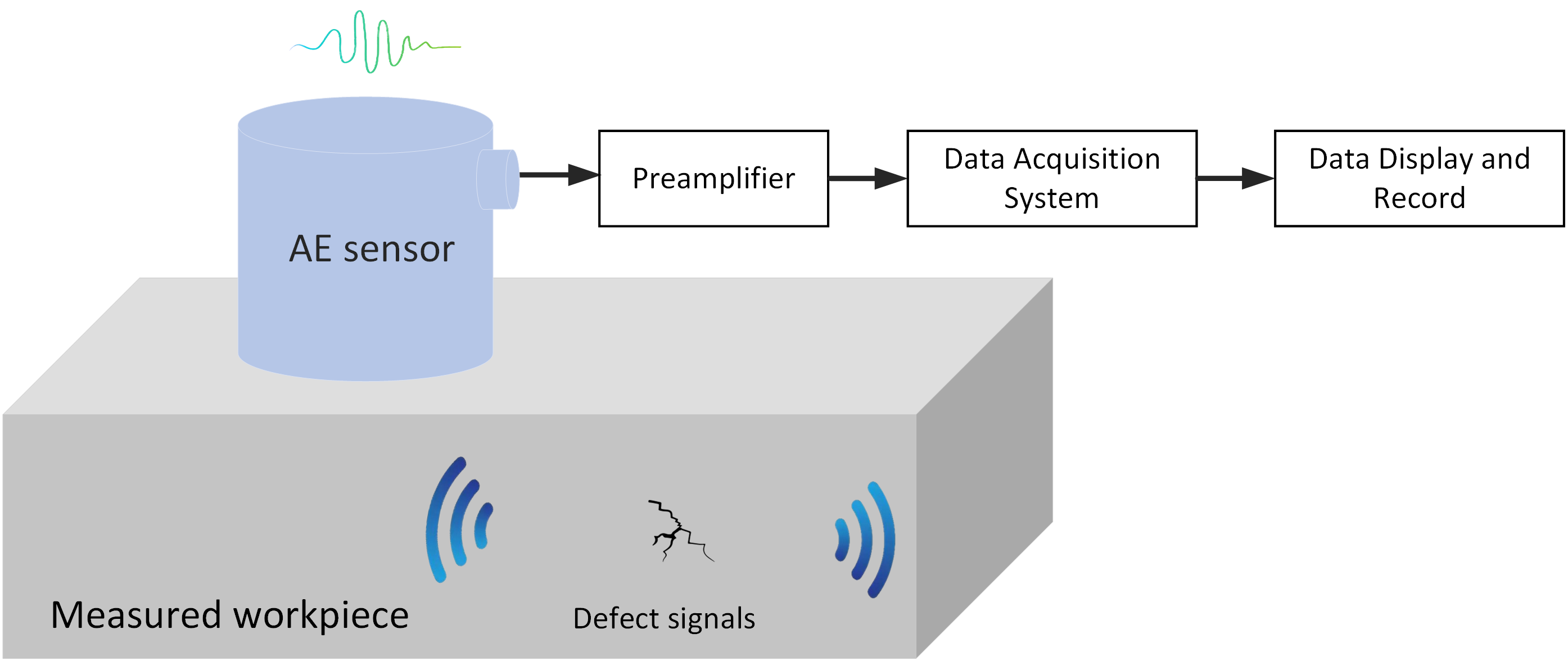

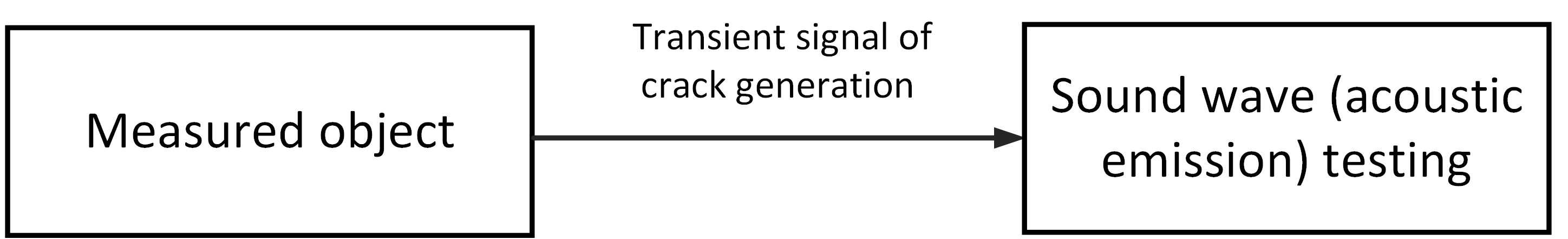

Acoustic wave (acoustic emission) testing is the acoustic wave (acoustic emission) signals received from the test sensing surface, which has nothing to do with other parts of the measured object.

2.Different Testing Phenomena

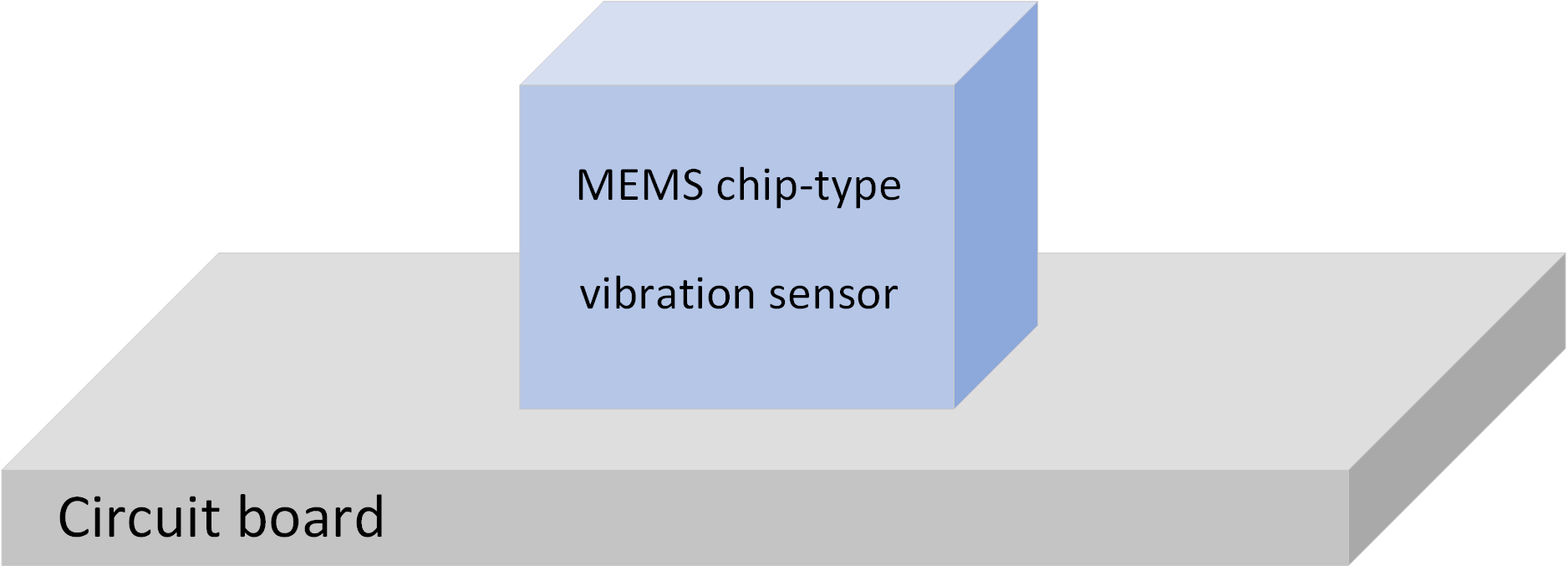

Vibration testing requires the vibration sensor and the measured object to be rigidly connected in order to perceive the vibration of the measured object. However, there is no need to have a specific acoustic wave receiving surface, and no need for acoustic coupling agent. For example, MEMS chip-type vibration sensors are usually mounted on a circuit board and do not need to be mounted on the surface of the measured object.

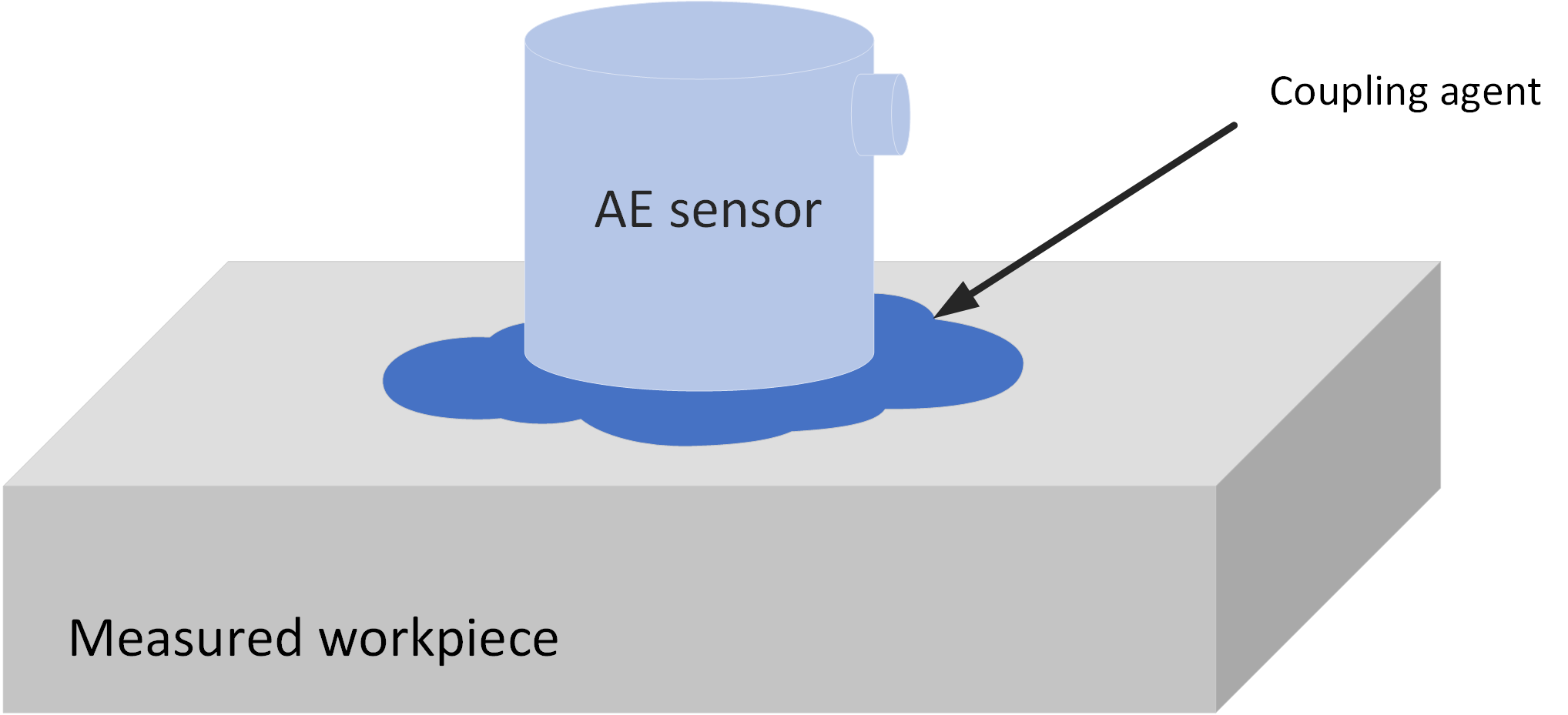

Acoustic wave (acoustic emission) testing sensor must be installed on the surface of the measured object to receive acoustic wave (acoustic emission) signals from inside of the measured object. The use of coupling agent is often necessary to obtain better acoustic wave (acoustic emission) signals, especially in the case of high frequency signals.

Vibration testing cannot capture transient signals like crack initiations such initial damage signals. Only when the crack initiation develops to a sufficient size and the initial damage accumulates to a large enough extent, the vibration of the measured object can be detected by the vibration sensor.

Acoustic wave (acoustic emission) testing can capture transient signals, such as initial damage like crack initiation and cracking. Acoustic waves (acoustic emission) testing can test the presence of signals, as well as changes of the signals.

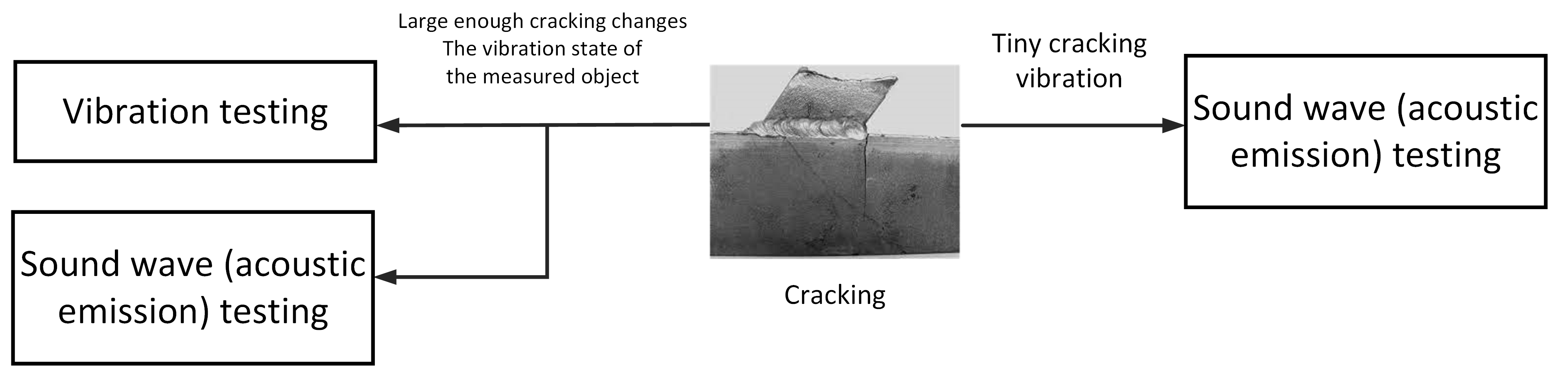

The damage process of most equipment is from a small initial transient damage to a large vibration state, whose steady-state changes. For example, the small cracking vibration change of structural parts cannot be captured by vibration testing but can be captured by acoustic wave (acoustic emission) testing. When the crack develops to a sufficient size to change the vibration state of the measured object, vibration signals can be captured, and acoustic wave (acoustic emission) signals can also be tested to get the change of acoustic wave.

Vibration signals are steady-state signals, which are not easily interfered by transient signals such as collisions and frictions of small particles. Acoustic wave (Acoustic emission) signal is transient signal, susceptible to all kinds of transient noise interference.