Red Bay Power Plant Pipeline Leakage Monitoring with RAEM1 System

Brief:On January 12, 2024, the RAEM1 acoustic emission monitoring system was successfully applied in the thermal pipeline leakage monitoring project of the generator set of Hongwan Power Plant in Guangdong Province led by China Special Inspection Institute.

On January 12, 2024, the RAEM1 acoustic emission monitoring system provided by Qingcheng Ltd. was successfully applied in the thermal pipeline leakage monitoring project of the generator set of Hongwan Power Plant in Guangdong Province led by China Special Inspection Institute, and its excellent performance and stability had been widely recognized by users.

Fig. 1 Red bay power plant picture

RAEM1 acoustic emission monitoring system is a high-precision and high-sensitivity acoustic emission monitoring product specially designed for the industrial field by Qingcheng Ltd. with its deep research and development experience. The sensor can capture the weak acoustic emission signal caused by leakage in the heat pipeline in real time, and analyze and process it through intelligent algorithm, accurately judge and grade the leakage signal, and locate the location of the leakage point, which provides strong technical support for the safe operation of the power plant.

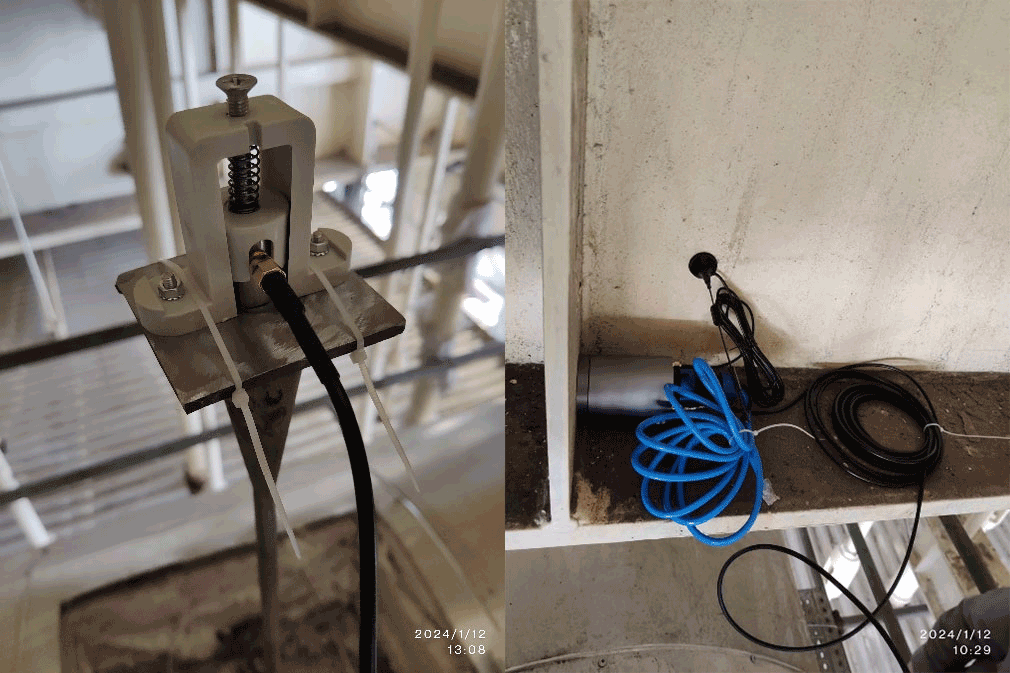

RAEM1 of Qingcheng Ltd. was used by China Special Inspection Institute for real-time monitoring of thermal pipeline leakage monitoring project of generator unit of Red Bay Power Plant in Guangdong Province. The sensor was installed in the key part of the thermal pipeline through the waveguide rod, and the running state of the pipeline was effectively monitored by collecting acoustic emission signals continuously. With high sensitivity and supporting cloud platform service features, the system provided an important basis for power plant timely maintenance.

Fig. 2 Device installation picture

This successful application marked an important breakthrough made by Qingcheng Ltd. in the field of acoustic emission monitoring technology for thermal pipelines of electric power facilities, and also provided a new technical solution for China Special Inspection Institute in the leakage monitoring of thermal pipelines of generator sets. In the future, China Special Inspection Institute and Qingcheng Ltd. will continue to deepen cooperation and jointly promote the wide application and development of acoustic emission detection technology in the field of industrial safety monitoring.