Acoustic Emission Detection of Gas Cylinders

Brief:Acoustic emission detection is an effective method to detect dynamic defects as a whole. The main purpose of acoustic emission detection and evaluation of in-service high-pressure gas cylinders is to determine the effective location and severity level of the AE source.

Case 1

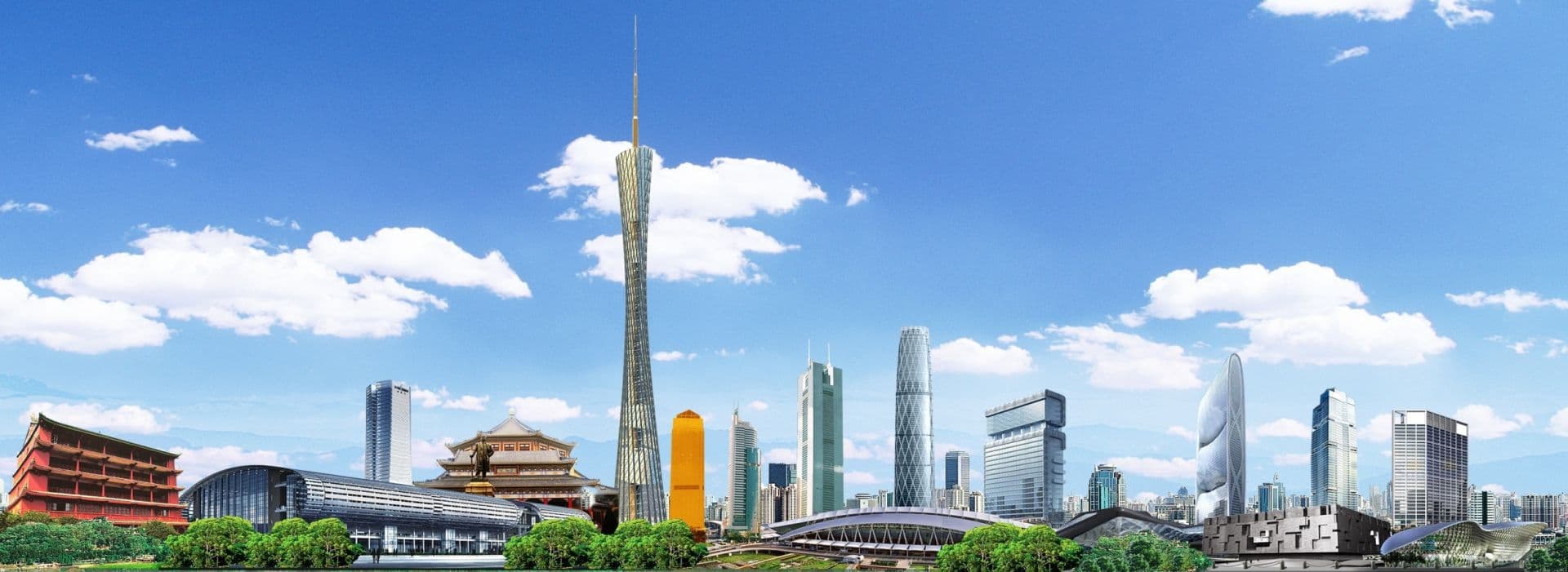

Acoustic emission detection of long tube trailer gas cylinders

Long tube trailer gas cylinder is a high-pressure storage and transportation equipment containing dangerous media. Whether timely and effective inspection can be carried out is the key to ensure its safe and reliable operation. Acoustic emission detection is an effective method to detect dynamic defects as a whole, which can save a lot of time, manpower and material resources when applied to the detection of long tube trailer gas cylinders.

Fig. 1 Field detection picture

Case 2

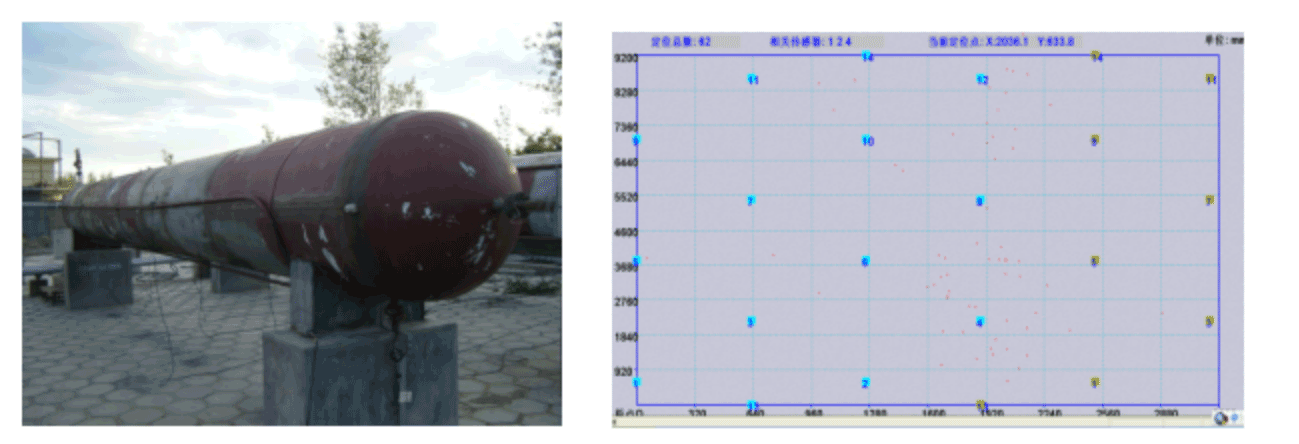

Acoustic emission detection of gas cylinders

The main purpose of acoustic emission detection and evaluation of in-service high-pressure gas cylinders is to determine the effective location and severity level of the AE source. For the gas cylinders without serious AE sources, they can be safely put into service. For cylinders determined to have serious AE sources, it is necessary to use conventional non-destructive testing methods for retesting.

At the invitation of PetroChina Karamay Petrochemical Company, Qingcheng Company used SAEU2S-18 acoustic emission instrument to test a high-pressure hydrogen cylinder with a capacity of 4 cubic meters. The results showed that 3 meaningful AE sources were grade B, and no other non-destructive testing was required for retesting. The test results prevented customers from blindly replacing gas cylinders because they were not clear about the condition of gas cylinders, and helped customers save the cost and time of replacing new gas cylinders.

Fig. 2 Field monitoring picture Fig. 3 Diagram of AE source location of gas cylinder