Acoustic emission detection of atmospheric tank floor corrosion

Brief:The main purpose of online acoustic emission detection of atmospheric storage tank is to judge whether there is leakage at the bottom of the tank, and finally evaluate the integrity of the storage tank by combining the local ultrasonic thickness measurement results and the local ultrasonic flaw detection results.

The main purpose of online acoustic emission detection of atmospheric storage tank is to judge whether there is leakage at the bottom of the tank, and finally evaluate the integrity of the storage tank by combining the local ultrasonic thickness measurement results of the tank wall or tank top and the local ultrasonic flaw detection results required by the acoustic emission detection results. Qingcheng Company has used acoustic emission technology to test the bottom plate of a number of customers' atmospheric storage tanks.

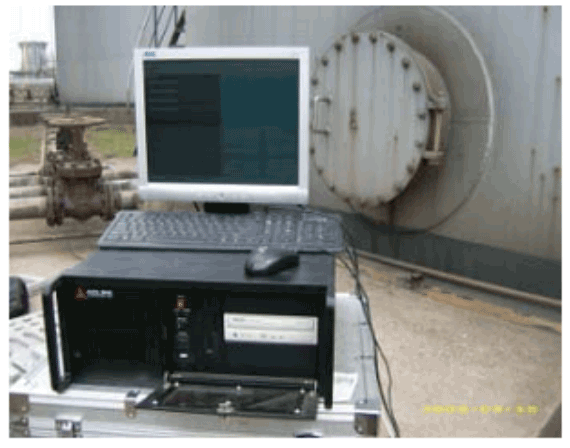

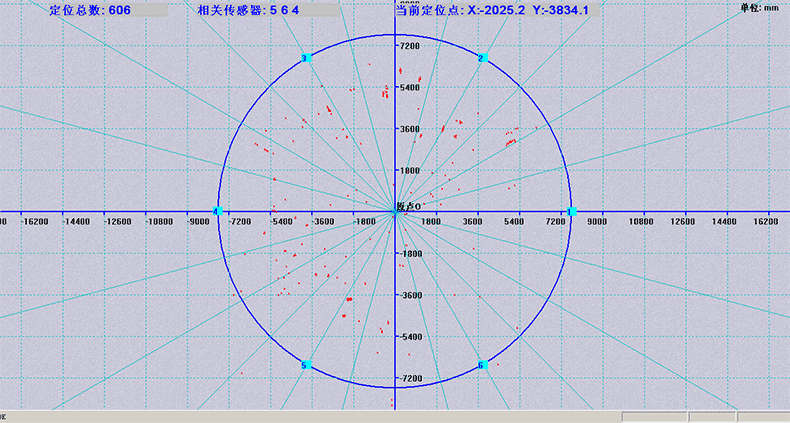

At the invitation of the oil depot of CNPC Ying Kou Sales Branch, Qingcheng Company used the SAEU2S-20 acoustic emission instrument of Qingcheng Company to carry out acoustic emission detection on the floor of the atmospheric pressure storage tank with 5000 cubic meters capacity and gasoline medium. According to the time difference positioning of the tank bottom, there were 152 effective positioning acoustic sources when maintaining pressure, and the acoustic source level was divided into class II (C<E≤10C):

there were slight signs of local corrosion of the tank bottom. Using the acoustic emission instrument of Qingcheng Company to detect the high-pressure hydrogen storage tank could help client to find potential safety hazards in time and prevent accidents.

Fig. 1 Field inspection picture

Fig. 2 Diagram of AE source location of tank floor corrosion