Your position:HOME > PRODUCTS > Acoustic Emission Sensors > Sensor Model List >

Acoustic Wave (Acoustic Emission)Sensor Model List

Model:

All acoustic wave(Acoustic Emission)sensor models

Description:

QingCheng develops and produces various and complete series of acoustic emission sensors to meet different application demands of acoustic emission non-destructive testing. Customized sensors are available if you need.

Features:

Compact structure design, sturdy and durable, high sensitivity, compatible with most of signal acquisition instruments in the market.

ENQUIRY NOWCONTACT:+86-20-32290092

QingCheng develops and produces various and complete series of acoustic emission sensors to meet different application demands of acoustic emission non-destructive testing.

Typical Application Selection:

In terms of acoustic emission applications, most actual applications are on the stable metallic structure, for example: pressure vessels. The anisotropy of this type of material is relatively small, as well as the attenuation coefficient of acoustic wave. The frequency band range is between 25kHz ~ 750kHz. It is suitable to choose resonant sensors (narrower band but high sensitivity).

Resonant narrow-band sensors with the centre frequency of 150kHz are widely used for testing acoustic emission signals in engineering materials, which are under the condition of metallic material and other applications.

Resonant narrow-band sensors have high sensitivity and SNR, which are inexpensive, and have various specifications. On the occasion of knowing the basic characteristics of sound source propagation, if customers who want to acquire the acoustic signals in a certain frequency range, or to enhance the systematic sensitivity, it is better to choose appropriate resonant sensors, for example, sound localization.

It should be pointed out that the so-called resonant narrow-band sensor is not only sensitive to a certain frequency signal, but to a certain frequency band. But the signal sensitivity is lower for other frequency bands.

List of Standard Acoustic Wave(AE)Sensors

(Customized sensors are available if you need)

| Sensor Model | Resonant Freq.(kHz) | Freq. Range(kHz) | Sensitivity Peak(dB) | Integral Preamp. | Size DxH (mm) | Weight (g) | Working Temp. (℃) | Case Material | Face Material | Protect Grade | Connector Type | Connector Location | Hold-down Model | Cables Model | Field of Applications |

| General Purpose Sensors | |||||||||||||||

| G150 | 150 | 60~400 | ﹥75 | / | Φ19×15 | 23 | -20~120 | SUS-304 | Ceramic | IP62 | M5 | Side | M20 | RG178/RG316 | Crack or fault diagnosis of metal |

| G80 | 80 | 20~180 | ﹥70 | / | Φ19×19.5 | 33 | -20~80 | SUS-304 | Ceramic | IP62 | M5 | Side | M20A | RG178/RG316 | Rock or partial discharge |

| G40 | 40 | 15~70 | ﹥75 | / | Φ22×36.8 | 82 | -20~120 | SUS-304 | Ceramic | IP62 | M5 | Side | Saddle type | RG178/RG316 | Rock or partial discharge, leakage, corrosion |

| G10 | / | 0.001~15 | >80 | / | Φ31×38 | 213 | -20~120 | SUS-304 | Ceramic | IP62 | BNC | Side | M36 | SYV-50-3/ STYV-50-2 | Leakage、slope de |

| G150/1 | 150 | 60~400 | ﹥75 | / | Φ19×15 | 50 | -20~120 | SUS-304 | Ceramic | IP68 | BNC on integral cable | Side | M20 | SYV-50-3/ STYV-50-2 | Crack or fault diagnosis of metal |

| G150/2 | 150 | 60~400 | >70 | / | Φ19×19.5 | 55 | -20~120 | SUS-304 | SUS-304 | IP68 | BNC on integral cable | Side | M20A | SYV-50-3/ STYV-50-2 | Crack or fault diagnosis of metal |

| G80/1 | 80 | 20~180 | ﹥70 | / | Φ19×19.5 | 59 | -20~80 | SUS-304 | Ceramic | IP68 | BNC on integral cable | Side | M20A | SYV-50-3/ STYV-50-2 | Rock or partial discharge |

| G10/1 | / | 0.001~15 | >80 | / | Φ31×38 | 214 | -20~120 | SUS-304 | Ceramic | IP62 | Single-core lemo | Side | M36 | RG178 | Leakage、slope detecting |

| Integral Preamplifier Sensors | |||||||||||||||

| GI150 | 150 | 60~400 | ﹥75 | 40dB28V | Φ30×36.5 | 120 | -20~50 | SUS-304 | Ceramic | IP62 | BNC | Side | M36 | SYV-50-3/ STYV-50-2 | Crack of metal, partial discharge, fiber |

| GI40 | 40 | 15~70 | ﹥75 | 40dB28V | Φ30×57 | 193 | -20~50 | SUS-304 | Ceramic | IP62 | BNC | Side | M36A | SYV-50-3/ STYV-50-2 | Partial discharge, leakage, corrosion |

| GI10 | / | 0.001~15 | ﹥80 | 26dB5V | Φ38.5×85 | 720 | -20~50 | SUS-304 | SUS-304 | IP68 | BNC on integral cable | Top | Self-magnetic | SYV-50-3/ STYV-50-2 | Buried pipeline leakage detection, slope geology |

| GI150/4 | 150 | 60~400 | ﹥75 | 40dB28V | Φ30×35 | 115 | -20~50 | SUS-304 | Ceramic | IP62 | M5 | Side | M36 | RG178/RG316 | Crack or fault diagnosis of metal |

| GI150/2 | 150 | 60~400 | >75 | 26dB5V | Φ22×25.5 | 38 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Crack or fault diagnosis of metal |

| GI150/3 | 150 | 60~400 | >75 | 34dB12V | Φ22×25.5 | 38 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Crack or fault diagnosis of metal |

| GI150/1 | 150 | 60~400 | ﹥75 | 40dB28V | Φ22×25.5 | 38 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Crack or fault diagnosis of metal |

| GI40/2 | 40 | 15~70 | ﹥75 | 40dB28V | Φ41×92 | 1280 | -20~50 | SUS-304 | SUS-304 | IP68 | BNC on integral cable | Top | / | SYV-50-3/ STYV-50-2 | Partial discharge, leakage, corrosion |

| GI35/2 | 40 | 15~70 | >75 | 34dB12V | Φ22×42.6 | 79 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Partial discharge, leakage, corrosion |

| GI35/1 | 40 | 15~70 | >75 | 26dB5V | Φ22×42.6 | 79 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Partial discharge, leakage, corrosion |

| GI35 | 40 | 15~70 | ﹥75 | 40dB28V | Φ22×42.6 | 79 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Partial discharge, leakage, corrosion |

| GI10/1 | / | 0.001~15 | ﹥80 | 34dB12V | Φ38.5×85 | 720 | -20~50 | SUS-304 | SUS-304 | IP68 | BNC on integral cable | Top | Self-magnetic | SYV-50-3/ STYV-50-2 | Buried pipeline leakage detection, slope geology |

| High Temperature Sensors | |||||||||||||||

| GH150/2 | 150 | 60~400 | >73 | / | Φ19×15 | 45 | -20~170 | SUS-304 | Ceramic | IP68 | BNC on integral cable | Side | H20 | SYV-50-3/ STYV-50-2 | HT environment |

| GH150/1 | 150 | 60~400 | >73 | / | Φ19×19.5 | 105 | -20~350 | Stainless Invar Steel | Stainless Invar Steel | IP68 | BNC on integral cable | Side | H20 | SYV-50-3/ STYV-50-2 | HT environment |

| GH150 | 150 | 60~400 | >60 | / | Φ19×19.5 | 125 | -20~600 | Stainless Invar Steel | Stainless Invar Steel | IP68 | BNC on integral cable | Side | H20 | SYV-50-3/ STYV-50-2 | HT environment |

| Intrinsically Safe Sensors | |||||||||||||||

| GSI150 | 150 | 60~400 | >73 | 26dB5V | Φ19×14 | 26 | -20~60 | SUS-304 | Ceramic | IP68 | SMA on integral cable | Top | / | RG178/RG316 | Crack or fault diagnosis of metal |

| GIS35 | 40 | 15~70 | >75 | 26dB5V | Φ22×42.6 | 76 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Leakage, corrosion |

| LS 5VDC Type: A | 35 | 15~70 | >65 | 26dB5V | Φ22×36.8 | 54 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | M36 | RG178/RG316 | Leakage, corrosion |

| LS 5VDC Type: B | 150 | 60~400 | >75 | 26dB5V | Φ22×25.5 | 39 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Crack or fault diagnosis of metal |

| Differential Sensors | |||||||||||||||

| GD150 | 150 | 60~400 | ﹥65 | / | Φ19×19.5 | 67 | -20~120 | SUS-304 | Ceramic | IP68 | Double-core BNC on integral cable | Side | M20A | / | Crack detection under high noise |

| GD40 | 35 | 15~70 | >65 | / | Φ22×25 | 106 | -20~120 | SUS-304 | Ceramic | IP68 | Double-core BNC on integral cable | Side | Saddle type | / | Partial discharge, leakage, corrosion |

| Miniature Sensors | |||||||||||||||

| GM150 | 150 | 70~280 | >68 | / | Φ7.8×19 | 5 | -20~120 | SUS-304 | Ceramic | IP62 | M5 | Top | Saddle type | RG178/RG316 | Crack or fault diagnosis of metal for narrow space |

| GM150/1 | 150 | 70~280 | >68 | / | Φ7.8×14 | 5 | -20~120 | SUS-304 | Ceramic | IP62 | M5 | Side | Saddle type | RG178/RG316 | Crack or fault diagnosis of metal for narrow space |

| Wideband Sensors | |||||||||||||||

| WI500 | 500 | 100~1000 | >65 | 40dB28V | Φ22×25.5 | 33 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Spectrum research, composite materials |

| W500 | 500 | 100~1000 | >65 | / | Φ19×15 | 19 | -20~120 | SUS-304 | Ceramic | IP62 | M5 | Side | M20 | RG178/RG316 | Spectrum research, composite materials |

| W800/1 | 600 | 50~800 | >65 | / | Φ19×15 | 45 | -20~80 | SUS-304 | Ceramic | IP68 | BNC on integral cable | Side | M20 | SYV-50-3/ STYV-50-2 | Spectrum research, composite materials |

| W800 | 600 | 50~800 | >65 | / | Φ19×15 | 18 | -20~80 | SUS-304 | Ceramic | IP62 | M5 | Side | M20 | RG178/RG316 | Spectrum research, composite materials |

| W500/1 | 500 | 100~1000 | >65 | / | Φ19×15 | 45 | -20~120 | SUS-304 | Ceramic | IP68 | BNC on integral cable | Side | M20 | SYV-50-3/ STYV-50-2 | Spectrum research, composite materials |

| WM500/1 | 500 | 100~1000 | >65 | / | Φ4.7×4.0 | 13 | -20~50 | SUS-304 | SUS-304 | IP68 | BNC on integral cable | Side | Saddle type | SYV-50-3/ STYV-50-2 | Spectrum research, composite materials |

| WI500/1 | 500 | 100~1000 | >65 | 34dB12V | Φ22×25.5 | 34 | -20~50 | SUS-304 | Ceramic | IP62 | SMA | Side | Saddle type | RG178/RG316 | Spectrum research, composite materials |

Note:

1.If the connector type is SMA, the protection grade can be upgraded to IP67. In that case, the cable must be water-proof. When connecting, it needs to rotate the sensor itself. The connector and the cable are integrated.

2.The water-proof sensors (either separated or integrated) are used in fresh water at room temperature. If there are salt lake water corrodes and sea water corrodes, or it requires to use in water at room temperature and above (80~170℃) for a long time, please contact us to solve the problem with composite material, which might increase the cost.

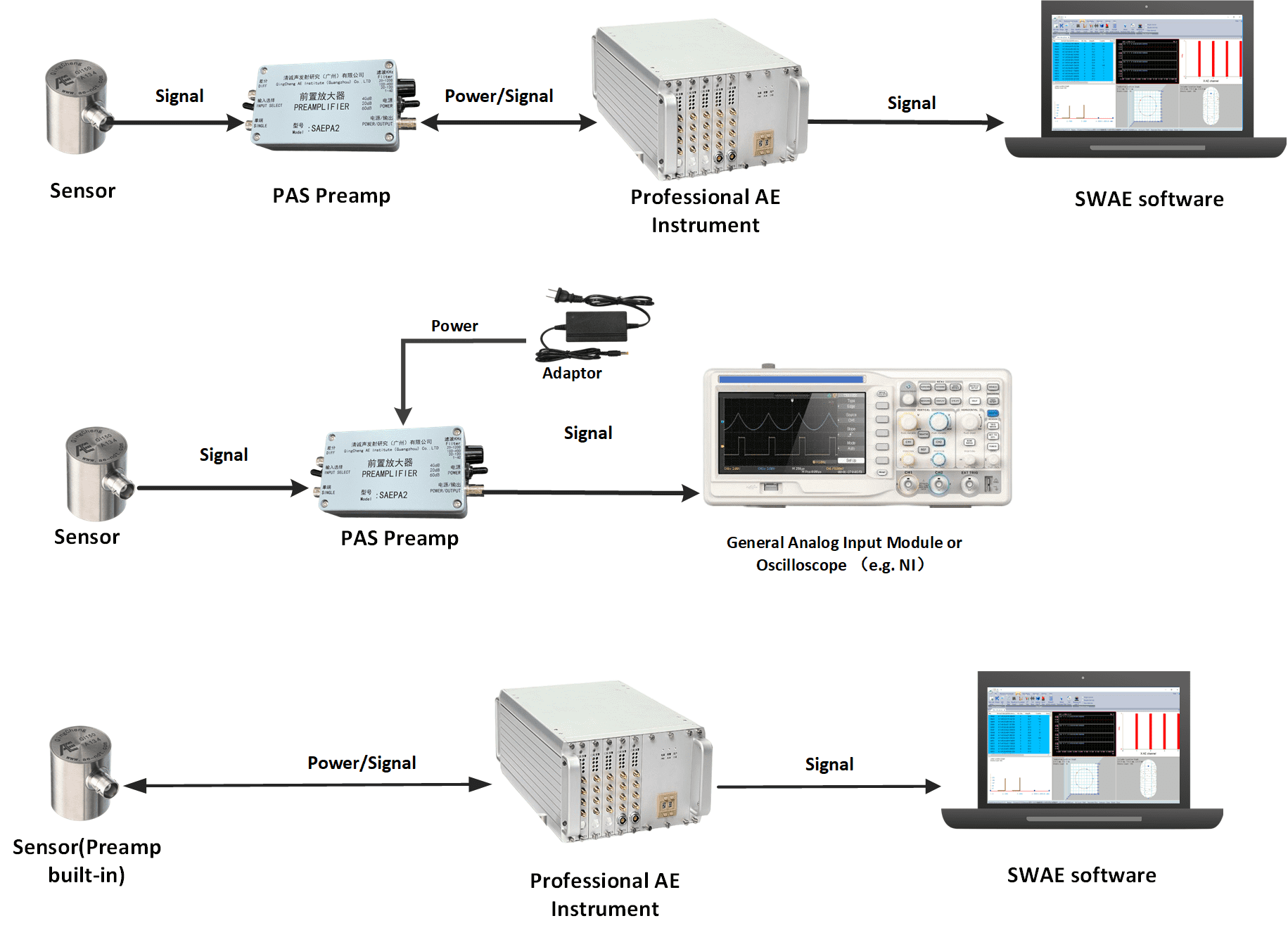

AE Sensor Connection diagram:

Further Information

![]() Acoustic Emission Sensor Calibration Standard Transfer Flow Chart.pdf

Acoustic Emission Sensor Calibration Standard Transfer Flow Chart.pdf