Your position:HOME > PRODUCTS > Benchtop AE System > RAEM AW(AE) Detection System >

RAEM1-6 Multi-channel Acoustic Emission Detection System

Model:

RAEM1-6

Description:

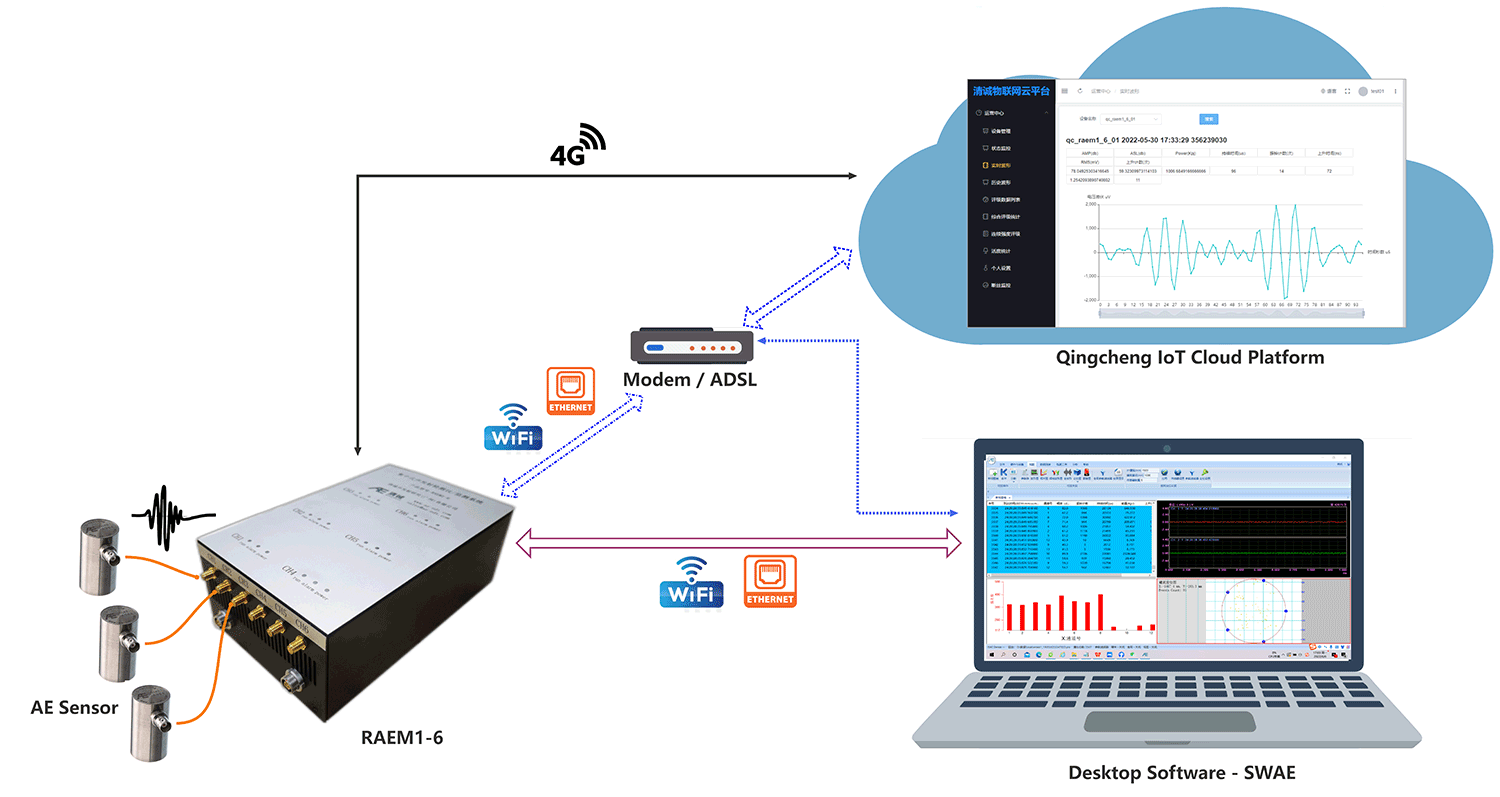

RAEM1-6 is a multi-channel AE detection and monitoring system. It can be used as a benchtop testing instrument with Windows software SWAE, but also as a remote wireless monitoring system with cloud platform or private servers.

Features:

Compact multi-channel (2 to 6 channels) design with Ethernet/4G/WiFi transmission.

ENQUIRY NOWCONTACT:+86-20-32290092

RAEM1-6 is a multi-channel intelligent IoT acoustic emission acquisition system that integrates automatic control signal acquisition, processing and analysis with clock synchronization and wired/wireless transmission. RAEM1-6 is a stand-alone AE instrument, which can be used as not only a benchtop AE testing equipment with Windows software SWAE, but also as a remote unattended online monitoring system with servers or clouds.

RAEM1-6 System Diagram with various communication

Features

- Standalone system: no need for manual start or stop operations. Once finish sensor installation and the configurations, it automatically starts when powering up.

- Flexible channels: users can order flexible channels in each case (from 2 up to 6 channels). Multiple RAEM1-6 devices can cascade to a 100+ and more channels AE system.

- Real-time data output: once receive signals from AE sensors, it processes and outputs the data, including AE featured parameters (arrival time, amplitude, counts, energy, rise time, rise counts, duration, RMS, ASL and more) and waveform and rating levels.

- External inputs: RAEM1-6 has 4 external input channels.

- Smart alarming: there are two alarm hardware outputs.

- Steady and reliable: Linux embedded system provides stability, reliability and security.

Easy Data Analysis

When using RAEM1-6 as a bench-top detector, it should be paired with the SWAE Software. SWAE is a professional acoustic emission data display and analysis software. RAEM1-6 collects and processes acoustic emission data, which is then sent to the SWAE software on the computer through a local area network for real-time analysis and display. The data display includes data table, waveform view, correlation graph, location view, FFT, cluster analysis, wavelet analysis, rating analysis and so on.

Application

| Channel Number | Up to 6 channels per case. It can cascade multiple devices to form a big system |

| Trigger Mode | Threshold trigger, external input trigger, software trigger |

| Sample Mode (Acquisition) | Envelop collection, fixed-length collection, streaming collection |

| Time Mode | Continuous, Schedule, or Interval timing |

| Sample Speed/Rate | The maximum sampling rate per channel is 2000,000 points per second (2000kHz) |

| Sample Resolution | 16-bit |

| Waveform Sample Length | Each channel can support up to 128,000 points per waveform sample length simultaneously, and channels can be set independently |

| Waveform Pre-sampling Length | The pre-sampling length can reach up to 128k sample points, and channels can be set independently |

| System Noise | Better than 30dB |

| Dynamic Range | Better than 70dB |

| Input Bandwidth | 10kHz-800kHz (-3dB, pass-through) |

| Analog Filter | Software selectable (kHz): 20-100kHz/ 20-400kHz/ 70-100kHz/ 70-400kHz/ Pass-through/ Bypassed |

| Digital Filter | Set any value in between 0 to 1000 kHz frequency range as pass-through/ high-pass/ low-pass/ band-pass filter |

| Preamp Voltage | 28V40dB / 12V34dB / 5V26dB |

| Output Data | Waveform, parameters, parameter ratings |

| AE Characteristic Parameters | Arrival time, amplitude, (ringing) count, energy, rise time, duration, RMS, ASL, frequency centroid, peak frequency, 5 partial power spectrum |

| Clock Synchronization | Synchronization options include RS485 (long-distance wired), cascaded (short-distance wired), WiFi (indoor wireless), or GPS (outdoor wireless). Synchronization accuracy within RAEM1-6 is ≤100ns, while the synchronization accuracy between multiple RAEM1-6 can be 500ns or better |

| Communication |

Ethernet port (Gigabit) / WiFi /4G Note: Ethernet port is compulsory. Users can add one wireless communication, either WiFi or 4G |

| External Input | Up to 4 inputs, input range from -10V to 10V. Maximum sample rate of 1MHz; external trigger capability |

| Alarm Output | 2 channels |

| Temperature Range | -20℃~60℃ |

| Power Input | Rated 24VDC/2A, operating voltage range 9V-36V |

| Dimension | Length × Width × Height: 23.2cm×12.5cm×5.2cm |

| Weight | 1.25kg |

Note:

- 1) Channel number: Users can choose to order flexible channel numbers per case. Each RAEM1-6 case can install from 2 to 6 AE boards. Each AE board has one channel and can connect to one sensor. Users may not be able to easily install additional AE boards in after manufacturing.

- 2) Communication modules: Ethernet port is compulsory. Users can order to add one wireless communication, either WiFi or 4G, for data transmission.

- 3) Phantom power to preamp: RAEM1-6 can only output one phantom power voltage to power preamplifier. It is non-programmable with factory-set preamplifier voltage. So when connecting, please make sure to only connect to the sensors/preamp with the same power.

- 4) Synchronization: options include RS485 (long-distance wired), cascaded (short-distance wired), WiFi (indoor wireless), or GPS (outdoor wireless). Synchronization accuracy within RAEM1-6 is ≤100ns, while the synchronization accuracy between multiple RAEM1-6 can be 500ns or better. If multiple RAEM1-6 devices are ordered, please choose one synchronization method. By default, it is cascaded (short-distance wired).

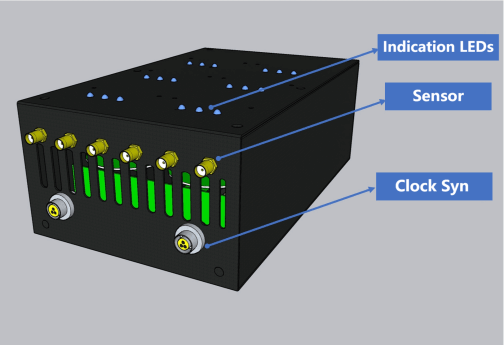

Front view of the RAEM1-6

Front View Function Description:

- Sensor: The sensor with built-in preamp or external preamp should be connected to these sensor ports. There are Chanel #1 to #6 from left to right. SMA connectors. Before connecting, please make sure the preamp voltage supplied by RAEM1-6 is matched with the connected preamp.

- Indicator light: During acquisition, this LED flashes each time there is acoustic emission signal in that channel.

- External Parameter Interface: There are four external input channels for input range from -10V to 10V. For more information, see Chapter 4.3.5 in the user manual.

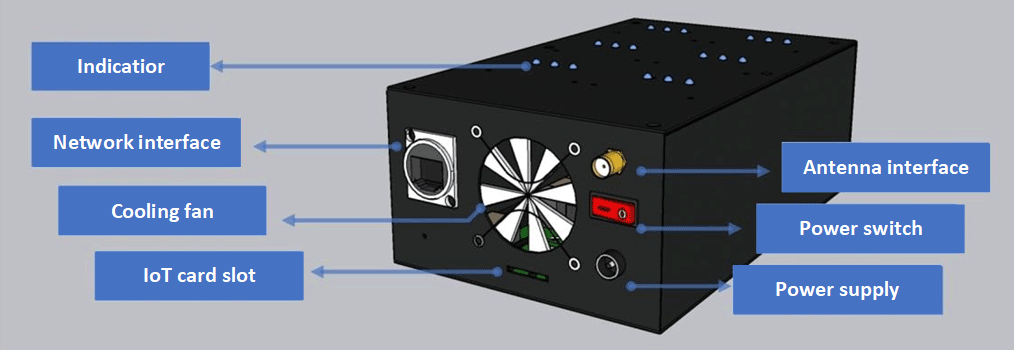

Back view of the RAEM1-6

Back View Function Description:

- RUN: The running LED indicates that RAEM1-6 is powered and is running.

- Power Interface: The input power voltage range is suggested from 11 to 36V.

- Alarm LED: After the alarm output is enabled, when there is alarm output signal, the alarm LED will light up once.

-

The next section of connection interface includes the following functions:

a) Alarm Interface: It has two alarm output interfaces. It supports three output forms: Pulse (high level 12V), active switching and passive switching. For more details, see Chapter 4.3.5 in the user manual.

b) CAN: under developing, not available.

c) RS485: RS485 is used for long distance clock synchronization of a cascade of multiple RAEM1-6. - Power Switch: indicates the power status. When the power adaptor is connected to power wall, the power LED is red. When the power button is pressed down, the LED turns green meaning the RAEM1-6 is powered on.

- Cascade Interface: Type-C connector. It is used for short distance clock synchronization of a cascade of other RAEM1-6.

- Ethernet Port: to connect to computer or router for communication.

- Card Slot: There are two card slots.

- The upper slot is 4G SIM (Nano SIM) card slot for 4G communication.

- SYNC: Synchronization Antenna, using GPS or WiFi.

- ANT: Antenna for wireless communication, WiFi or 4G.

Note:

- 1) Channel number: Users can choose to order flexible channel numbers per case. Each RAEM1-6 case can install from 2 to 6 AE boards. Each AE board has one channel and can connect to one sensor. Users may not be able to easily install additional AE boards in after manufacturing.

- 2) Communication modules: Ethernet port is compulsory. Users can order to add one wireless communication, either WiFi or 4G, for data transmission.

- 3) Phantom power to preamp: RAEM1-6 can only output one phantom power voltage to power preamplifier. It is non-programmable with factory-set preamplifier voltage. So when connecting, please make sure to only connect to the sensors/preamp with the same power.

- 4) Synchronization: options include RS485 (long-distance wired), cascaded (short-distance wired), WiFi (indoor wireless), or GPS (outdoor wireless). Synchronization accuracy within RAEM1-6 is ≤100ns, while the synchronization accuracy between multiple RAEM1-6 can be 500ns or better. If multiple RAEM1-6 devices are ordered, please choose one synchronization method. By default, it is cascaded (short-distance wired).

RAEM1-6 can be used as a benchtop detection data acquisition instrument (DAQ) for acoustic emission (AE) testing. But RAEM1-6 is not only the DAQ but also include data transmission modules so that the results can transmitted from RAEM1-6 to computers/servers through wiring or wireless communication.

There are two kinds of hardware connections from the AE sensor to RAEM1-6:

1)The integral AE sensor has preamplifier built-in:

2)The general AE sensor requires external preamplifier:

In “Detection Mode”, RAEM1-6 is connected to local network via Ethernet cable or WiFi (Hotspot or router mode), and transmits the data to SWAE for display and data analysis. Below is the data transmission methods to the computer to use SWAE analysis software.

Multiple RAEM1-6 can cascade to a larger AE system for AE testing or monitoring of large equipment.

On the other hand, RAEM1-6 can be used as a remote unattended monitoring system using wireless communications to cloud platform or servers for long term monitoring purpose.

RAEM1-6 Multi-channel Acoustic Emission Online Monitoring System

![]() NEW RAEM1-6 Users Manual.pdf

NEW RAEM1-6 Users Manual.pdf

![]() User's Manual.pdf

User's Manual.pdf

![]() Quick Start Guide.pdf

Quick Start Guide.pdf

![]() RAEM1-6 Introduction and Hardware Connection Guide

RAEM1-6 Introduction and Hardware Connection Guide ![]()

Note:

- The videos are using the old version RAEM1-6. The principle is the same but just the outlook and the configuration software interface change. So please refer to the video and also follow the new users manual. If you have doubts, feel free to contact us.