Aerial Work Platform AE Testing Monitoring

Brief:According to ASTM F914-03 standard, aerial work platform needs to undergo regular quality and safety testing. Early detection of early stage of cracks or dangers to avoid major accidents, to ensure the safety of mechanical use and of the aerial work personnel is of great significance.

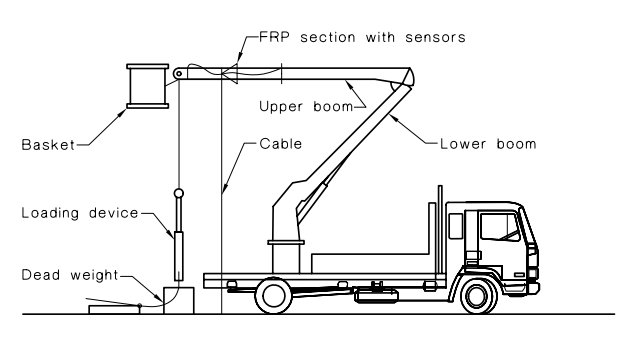

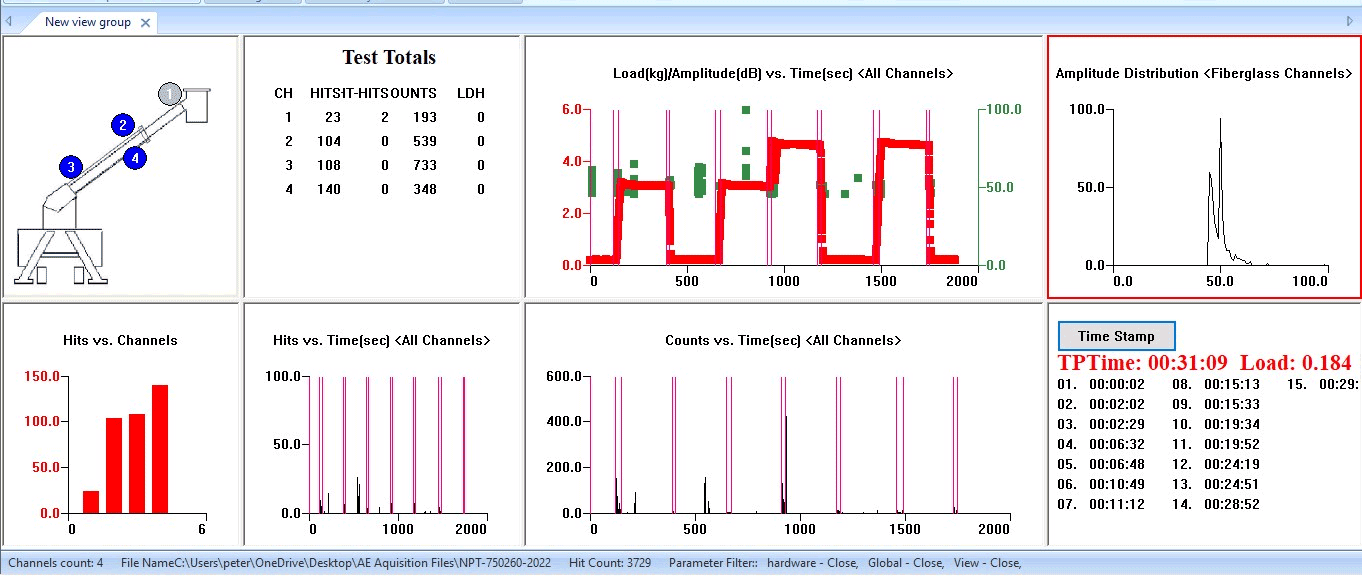

Fig.1 Illustration of typical boom position and testing set-up

Overview:

Aerial personnel work platforms (also known as Bucket trucks) have become more popular in the industrial constructions and civil engineering applications. But its safety issue also raise more and more concerns. Based on some safety standards in some developed countries, the aerial work platform needs to undergo regular quality and safety testing. Early detection of early stage of cracks or dangers to avoid major accidents, to ensure the safety of mechanical use and of the aerial work personnel is of great significance.

Acoustic emission detection technology is widely used as the detection technology on aerial work platform around the world. According to ASTM F914-03 standard, This test method consists of applying a predetermined load to an aerial personnel device while it is being monitored by sensors that are sensitive to acoustic emissions (AE) caused by active defects. These acoustic emissions can be generated by, but are not limited to, the following: crack nucleation movement or propagation in the metal components; or matrix crazing, de-lamination or fiber breakage of the fiberglass reinforced plastic (FRP) material; or both.

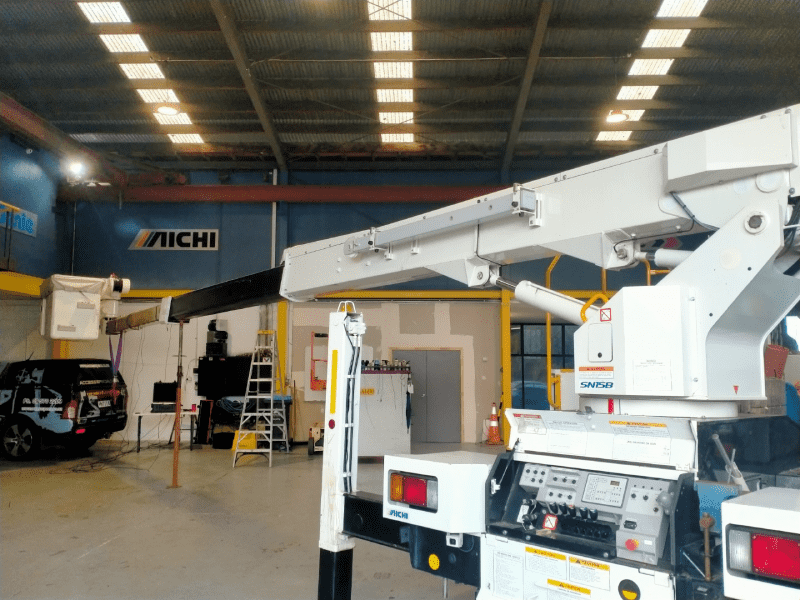

Fig.2 Scene picture

Client:

Service company in Mexico, or New Zealand, etc

Selected products:

| Sensors |

GI40 used on fiberglass components; GI150 used on metal components |

| DAQ | SAEU3H multichannel instrument Or RAEM1 series monitoring system (RAEM1-6) |

| Fixed Method |

Rubber bands on fiberglass components; Magnetic holders on metal components |

| Other Components | External parameter box for external inputs (i.e. load cells - self source) |

| Software | SWAE analysis software (AWPT version) - specific designed version for aerial work platform testing report purpose |

Project Process and Results:

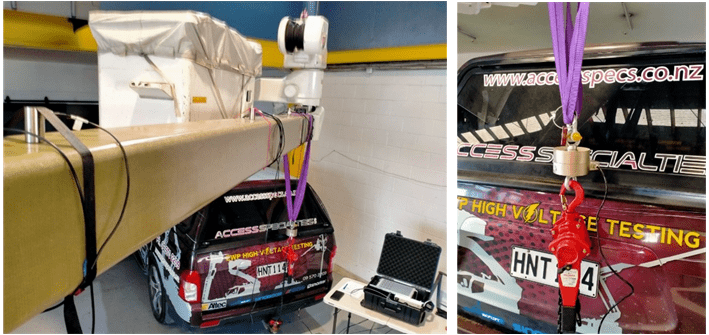

Fig.3 Sensors and load cell installation

AE sensors collect AE signals from Aerial work platform, and transmit them to DAQ for analysis and processing, and then transmit the data to SWAE analysis software for further analysis and display. So that users can intuitively see the status of aerial work platform throughout the whole loading process. The SWAE (AWPT version) software is designed specially for aerial work platform purpose and follows ASTM F914-03 standard. By default, there are 8 views preloaded in the software for immediate operations:

- Test article

- Test Totals table

- Loads/Amplitude vs. Time

- Amplitude distribution

- Hits vs. Channels

- Hits vs. Times

- Counts vs. Time

- Total Performance Time

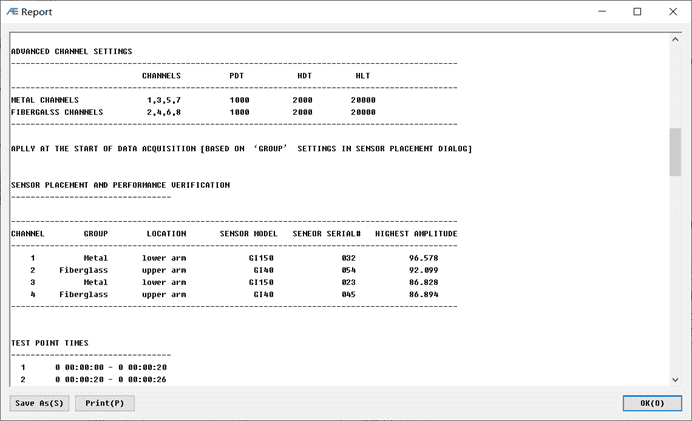

At the end of the test, a test report can be generated from the software including all the test results obtained from the test.

Fig.4 Real-time sampling interface

Fig.5 U3H software testing report